Blog

What Tests And Certifications Are Required for Reliable Outdoor Silicone Neon Flex Products?

What Tests And Certifications Are Required for Reliable Outdoor Silicone Neon Flex Products?

Ryan Lee.UpdatedJune 26, 2025|9 mins Read

Introduction

Outdoor silicone neon flex is commonly used for exterior lighting applications, including building facades, landscape architecture, roads and bridges, and waterscape lighting. These products must endure harsh conditions and variable challenges during installation and throughout their lifespan, requiring exceptionally high standards of quality, reliability, and long-term stability. Therefore, comprehensive testing and certification that address the product’s full lifecycle quality control must be completed during the research and development(R&D) phase and before mass production.

This article references the tests and certifications achieved by COLORS Lighting's Arch Neon series neon flex, detailing test items and procedures, technical standards, and professional certifications to provide customers with a trusted reference for selecting high-quality, reliable products in demanding environments.

1. Core Testing Items

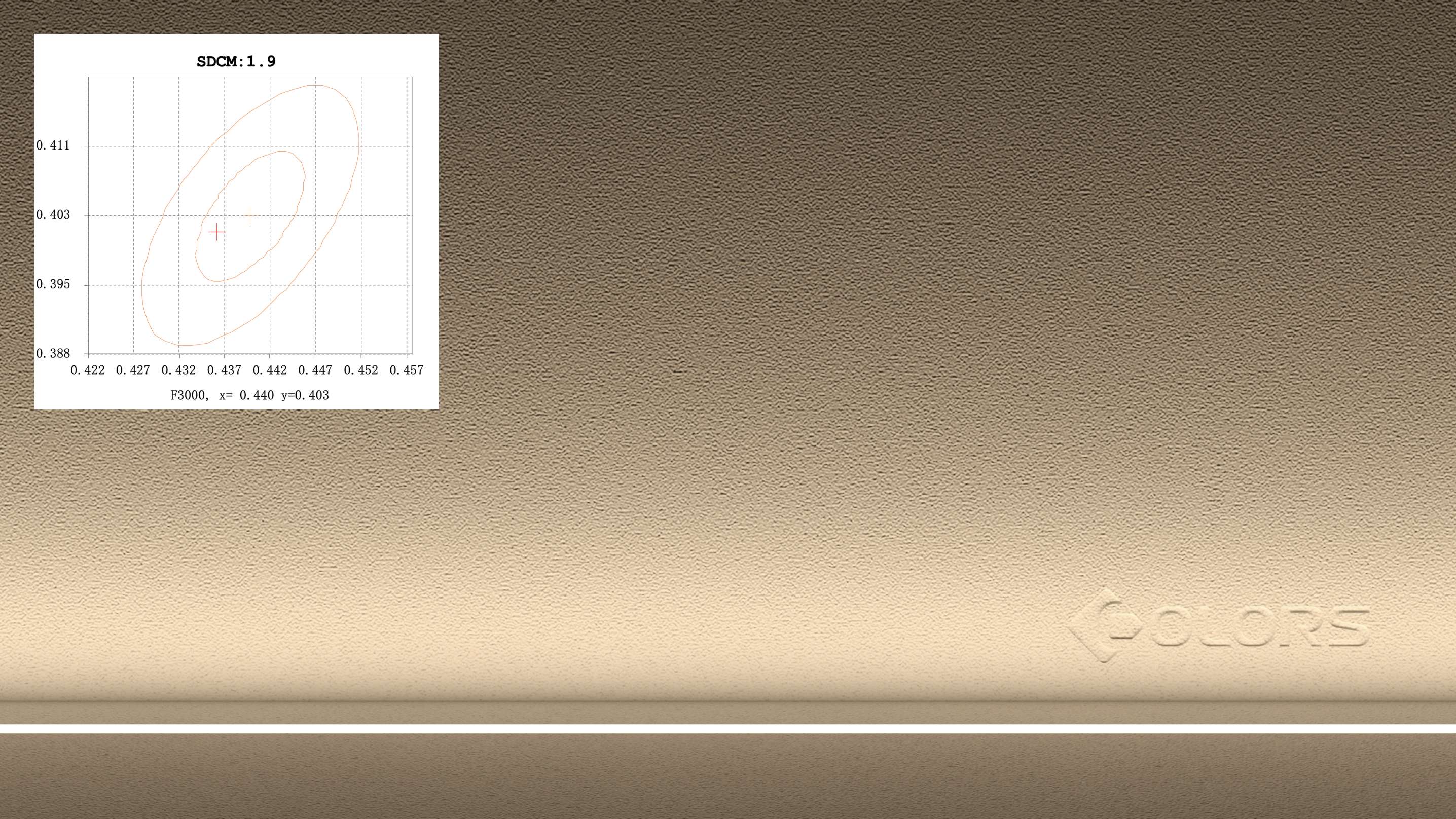

1.1 Optical Performance

- Spectral Test:

- Test Content: Correlated Color Temperature (CCT), Color Rendering Index (CRI), Chromaticity Deviation (SDCM), Luminous Flux.

- Purpose: Ensure color consistency and lighting effects meet design requirements.

- Standard: CIE 024 / IES LM-79.

- IES File Test:

- Test Content: Light distribution curve, beam angle, luminous intensity distribution.

- Purpose: Verify optical design compatibility with architectural structures.

- Standard: IES LM-63 / EN 13032.

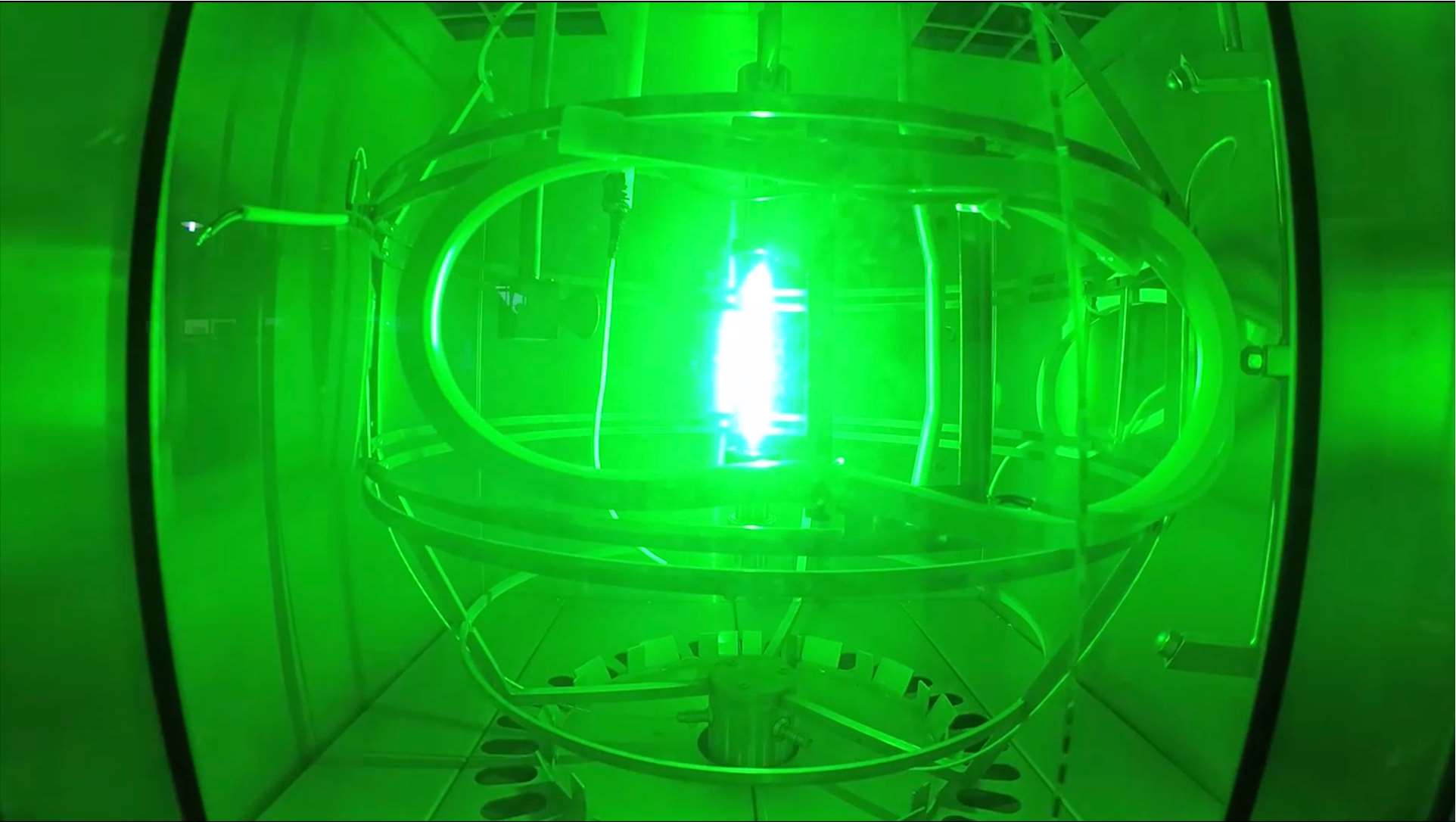

- Lumen Maintenance Test:

- Test Content: Luminous flux retention rate after continuous aging (e.g., 1,000 hours).

- Purpose: Evaluate long-term lumen depreciation.

- Standard: IES LM-80 / TM-21.

- Color Consistency Test:

- Test Content: ΔE < 0.5 (same batch), Δuv < 0.002.

- Standard: ANSI C78.377.

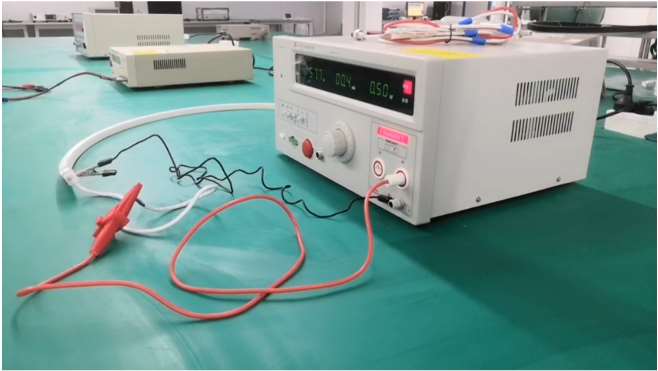

1.2 Electrical Safety

- High Voltage Test:

- Test Content: 3,750V AC/1 min or equivalent DC voltage.

- Purpose: Validate insulation material strength to prevent electric shock.

- Standard: IEC 60598-1 Sec. 10.

- Leakage Current Test:

- Test Content: Leakage current values under normal/fault conditions.

- Purpose: Prevent user contact with live parts.

- Standard: IEC 60598-1 Sec. 13.

- Insulation Resistance Test:

- Test Content: Insulation resistance ≥2 MΩ at 500V DC.

- Purpose: Ensure electrical isolation reliability.

- Standard: IEC 60598-1 Sec. 15.

1.3 Protection Rating

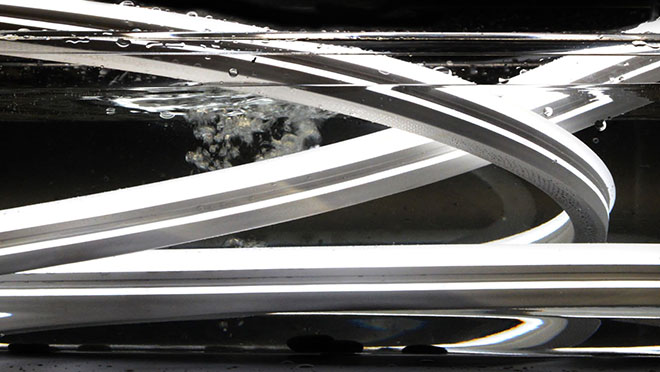

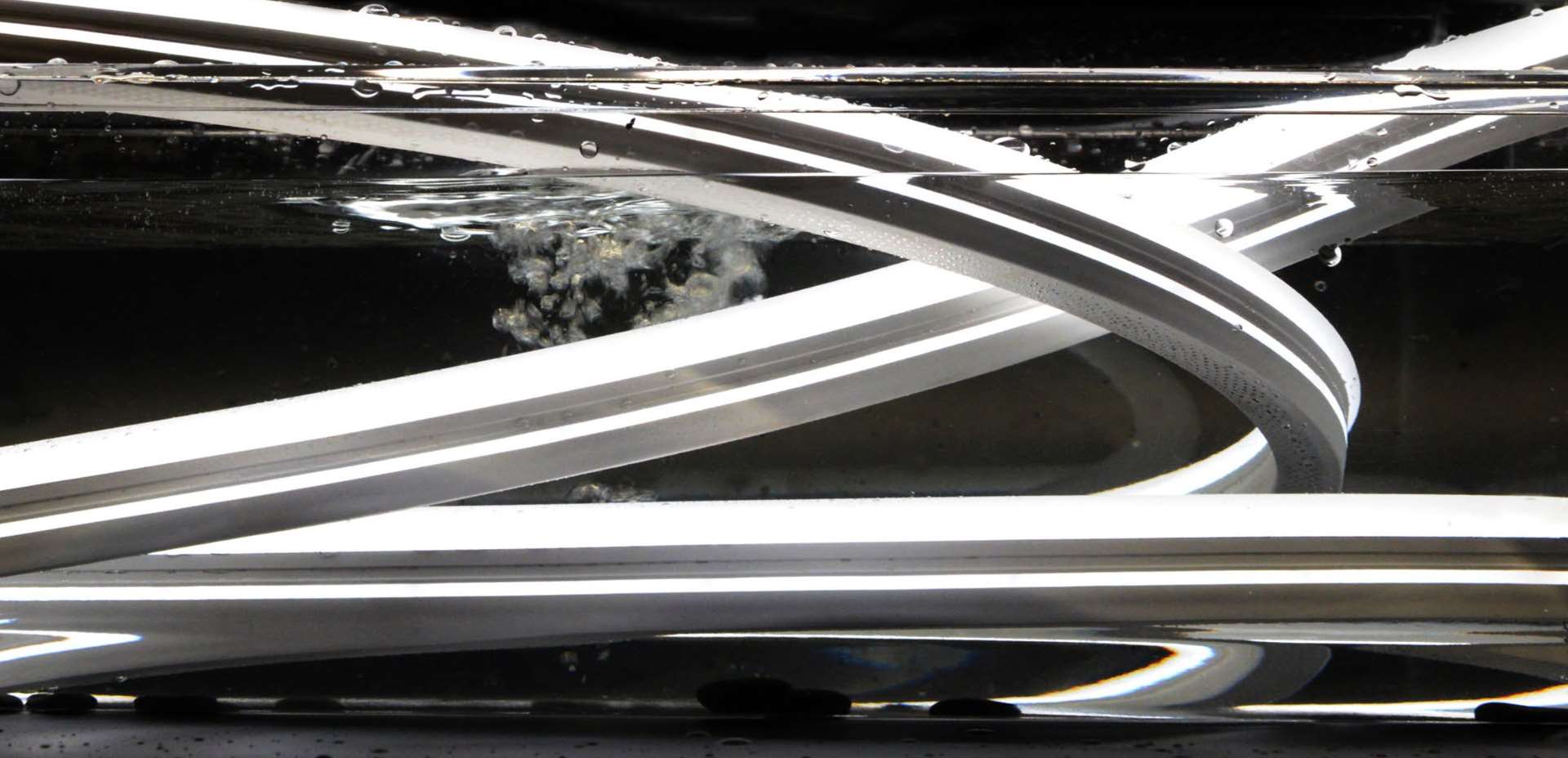

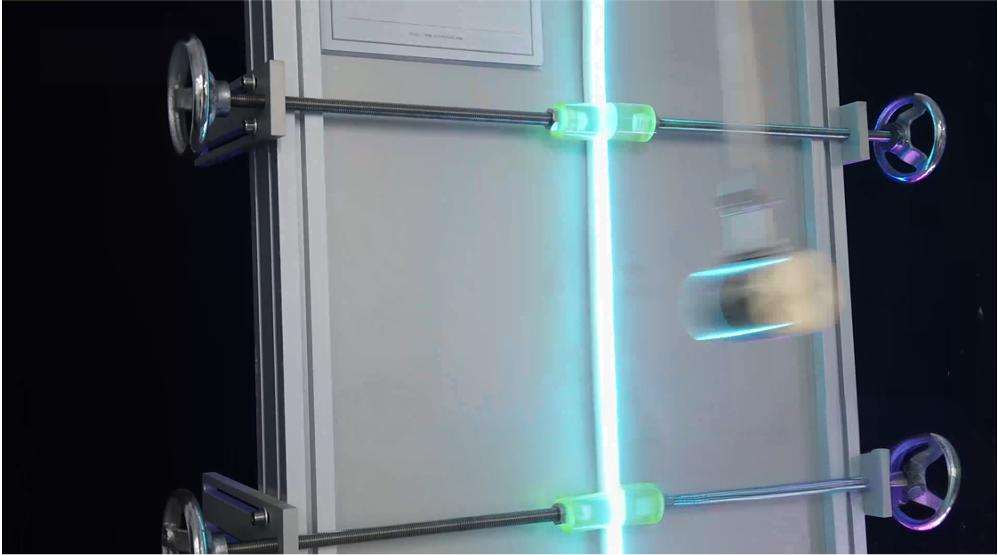

- IP Dust & Waterproof Test:

- Test Content: IP65/IP67 spray, immersion, and salt-alkali immersion tests.

- Purpose: Ensure operation in rain, dust, and high-salt environments.

- Standard: IEC 60529.

|

|

- Dynamic Waterproof Test:

- Test Content: IP68 (1m depth × 72h) + water jet impact (12L/min × 3min).

- Standard: Enhanced IEC 60529.

- Connector Protection Test:

- Test Content: IP68 validation with waterproof potting sealant.

1.4 Weather Resistance

- Thermal Cycling Test:

- Test Content: -40℃ to +85℃ temperature shock.

- Purpose: Verify structural stability under extreme temperatures.

- Standard: IEC 60068-2-14.

|

|

- Damp Heat Test:

- Test Content: 85% RH + 85℃ for 168 hours.

- Purpose: Prevent circuit corrosion from moisture penetration.

- Standard: IEC 60068-2-78.

- UV Aging Test:

- Test Content: 500 hours of UV-B radiation.

- Purpose: Resist silicone yellowing and embrittlement.

- Standard: ISO 4892-3.

- Salt Spray/Salt-Alkali Immersion:

- Test Content: 5% NaCl spray for 96 hours.

- Purpose: Resist corrosion in coastal environments.

- Standard: IEC 60068-2-52.

- Chemical Solvent Resistance:

- Test Content: 100 wipes with alcohol/acetone.

- Purpose: Validate surface print durability.

- Standard: ISO 2812-3.

- Acid Rain Simulation:

- Test Content: pH 3.5 solution spray for 48 hours.

- Standard: IEC 60068-2-43.

1.5 Mechanical Reliability

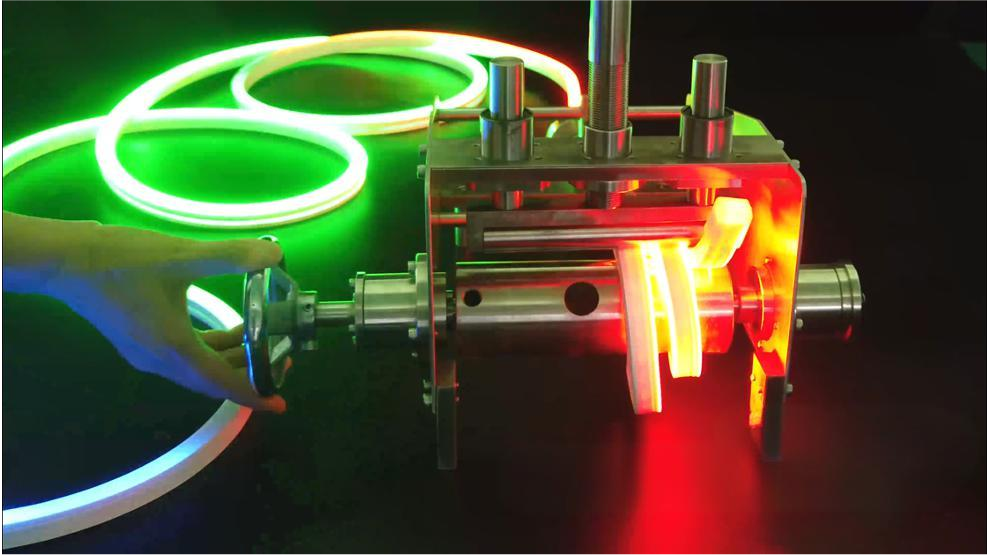

- Bending/Twisting Test:

- Test Content: 180° bending × 100 cycles + axial twisting.

- Purpose: Verify deformation tolerance during installation.

- Standard: IEC 62868-2-2.

|

|

- Impact Test:

- Test Content: 0.5J mechanical shock.

- Purpose: Simulate transportation/installation impact.

- Standard: IEC 60068-2-75.

- Tensile Strength Test:

- Test Content: Adhesion force between silicone and wires/PCB.

- Purpose: Prevent detachment under stress.

- Standard: ISO 37 / ASTM D412.

|

|

1.6 Material Performance

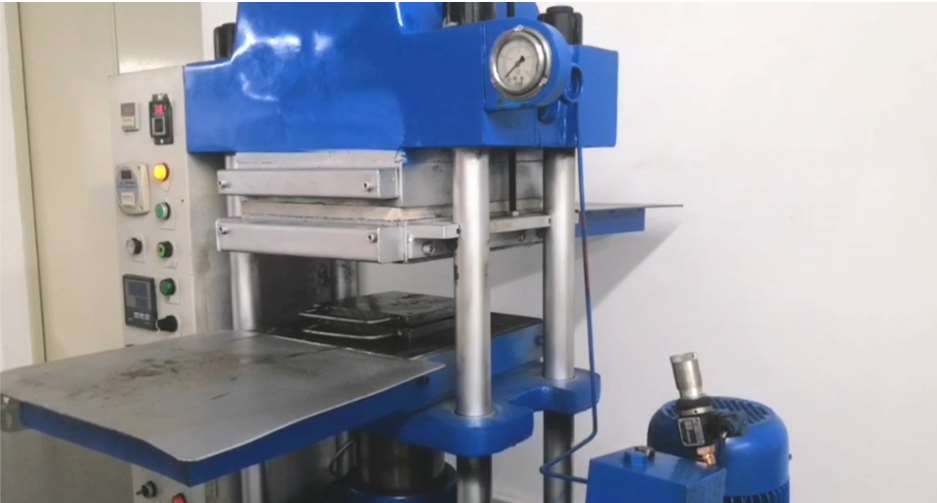

- Silicone Hardness Test:

- Test Content: Shore A hardness (typical: 50-80A).

- Purpose: Balance flexibility and crack resistance.

- Standard: ISO 7619 / ASTM D2240.

|

|

- Flame Retardancy Test:

- Test Content: Vertical burning rating (V-0).

- Purpose: Prevent fire spread and toxic gas release.

- Standard: IEC 60695-11-10.

- Low-Temperature Flexibility:

- Test Content: Coiling test at -25℃.

- Standard: UL 2388.

- Process Validation:

- Test Content: Pre-processing with tablet press/punching machine.

|

|

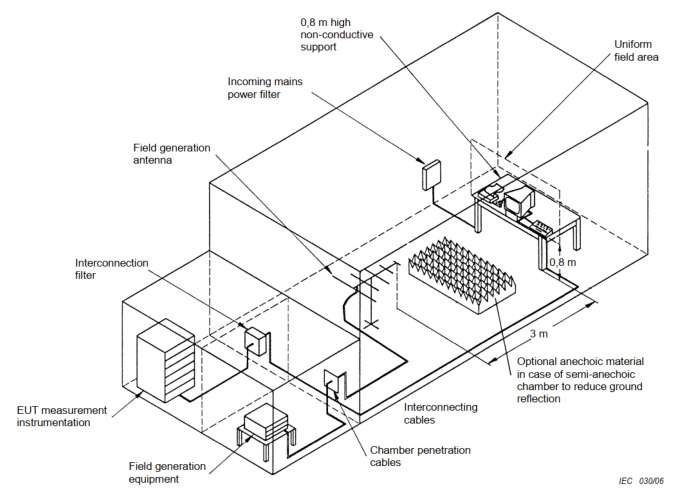

1.7 EMC Electromagnetic Compatibility

- Radiated Emission (RE):

- Test Content: Electromagnetic field intensity (30MHz-1GHz).

- Purpose: Avoid interference with nearby electronics.

- Standard: CISPR 15 / FCC Part 15.

- Immunity (RS/EFT):

- Test Content: Tolerance to RF fields/electrical fast transients.

- Purpose: Ensure stability under electromagnetic interference.

- Standard: IEC 61000-4-3/4.

1.8 RGBW Control-Specific Tests

- PWM Dimming Compatibility:

- Test Content:

- Brightness linearity (10%-100% duty cycle).

- Flicker index (SVM/Pst LM) across 100Hz–10kHz.

- Stability under ±10% voltage fluctuation.

- Purpose: Prevent eye fatigue and control-chip interference.

- Criterion: SVM < 0.4.

- Test Content:

- DMX512 Protocol Stability:

- Test Content:

- Packet loss rate < 0.1% (512 channels).

- Latency ≤20ms (100m transmission).

- Multi-controller conflict recovery.

- Noise immunity (parallel routing with power cables).

- Purpose: Ensure signal synchronization in complex EM environments.

- Criterion: Bit error rate ≤10⁻⁶.

- Test Content:

- EMC Burst Immunity (EFT):

- Test Content:

- ±4kV/5kHz bursts (power ports, 1min).

- ±2kV/5kHz bursts (DMX/RDM ports).

- Zero functional failure (e.g., reset, color shift).

- Purpose: Simulate lightning strikes/grid switching.

- Criterion: Performance Level B (temporary dimming allowed).

- Test Content:

2. Key Certification Requirements

2.1 Safety Certification

- IEC/EN 60598-2-20 (Neon flex-specific safety standard).

- UL 2388 (North American safety standard).

- GB 7000 (China Compulsory Certification).

2.2 EMC Certification

- CE-EMC (EU) / FCC (USA) / RCM (Australia).

2.3 Energy & Eco Certification

- ERP Lot 9 (EU energy efficiency).

- RoHS/REACH (hazardous substance restrictions).

2.4 IP Rating Certification

- IP65/IP67/IP68 certificates (issued by accredited labs).

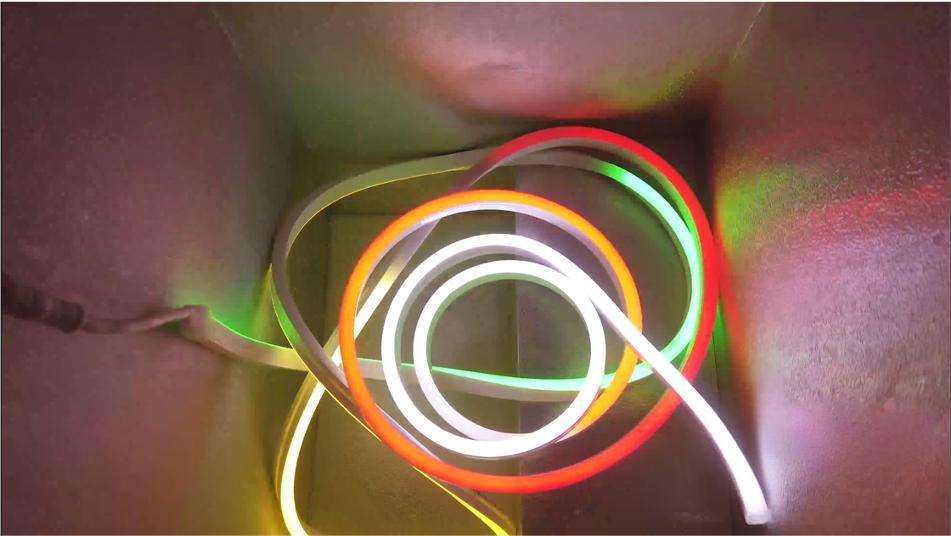

3. COLORS Lighting-ARCH NEON Series Silicone Neon Flex

COLORS Lighting’s upgraded ARCH NEON series includes:

· AF Weather-Resistant Series neon flex: For extreme climates.

· AH High-Efficacy Cuttable Series neon flex: Cut at any point.

· AW Underwater Series neon flex: IP68-rated for use in pools and fountains.

Engineered for building facades, landscape architecture, roads and bridges, and waterscape lighting, these products deliver exceptional weather resistance, reliability, and optical performance. For professional lighting solutions and project inquiries, contact us for a quote.

Conclusion

COLORS Lighting, the LED linear lighting solutions provider, specialises in the research, development, and manufacturing of high-quality lighting products, which have been certified by all major national markets and are exported to more than 100 countries and regions worldwide.

Our product portfolio covers Neon Strips, LED Strips, Infinite Lights, Linear Lights, Track lights, and Downlights. COLORS Lighting provides integrated and professional lighting solutions for residential, hotel, office, commercial, and outdoor spaces.

We have a professional lighting design team, key projects to provide pre-design planning, mid-term selection simulation, post-installation and commissioning of professional support. For key projects, we can cooperate with designers and engineers to deepen the pre-sale product application program. Welcome to contact us and tell us which products you prefer, or let us know what type of lighting solution you need. Let us help your lighting project! COLORS Lighting, Colorful Life!