Blog

How To Choose A Quality LED Tape Light Manufacturer And Supplier 2025?

How To Choose A Quality LED Tape Light Manufacturer And Supplier 2025?

Joyce Alva.UpdatedAugust 4, 2025|10 mins Read

Introduction

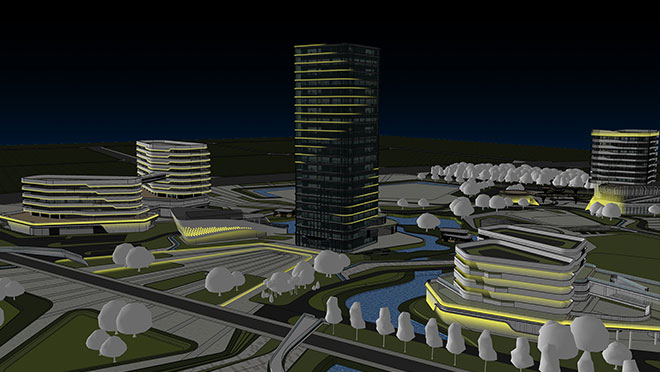

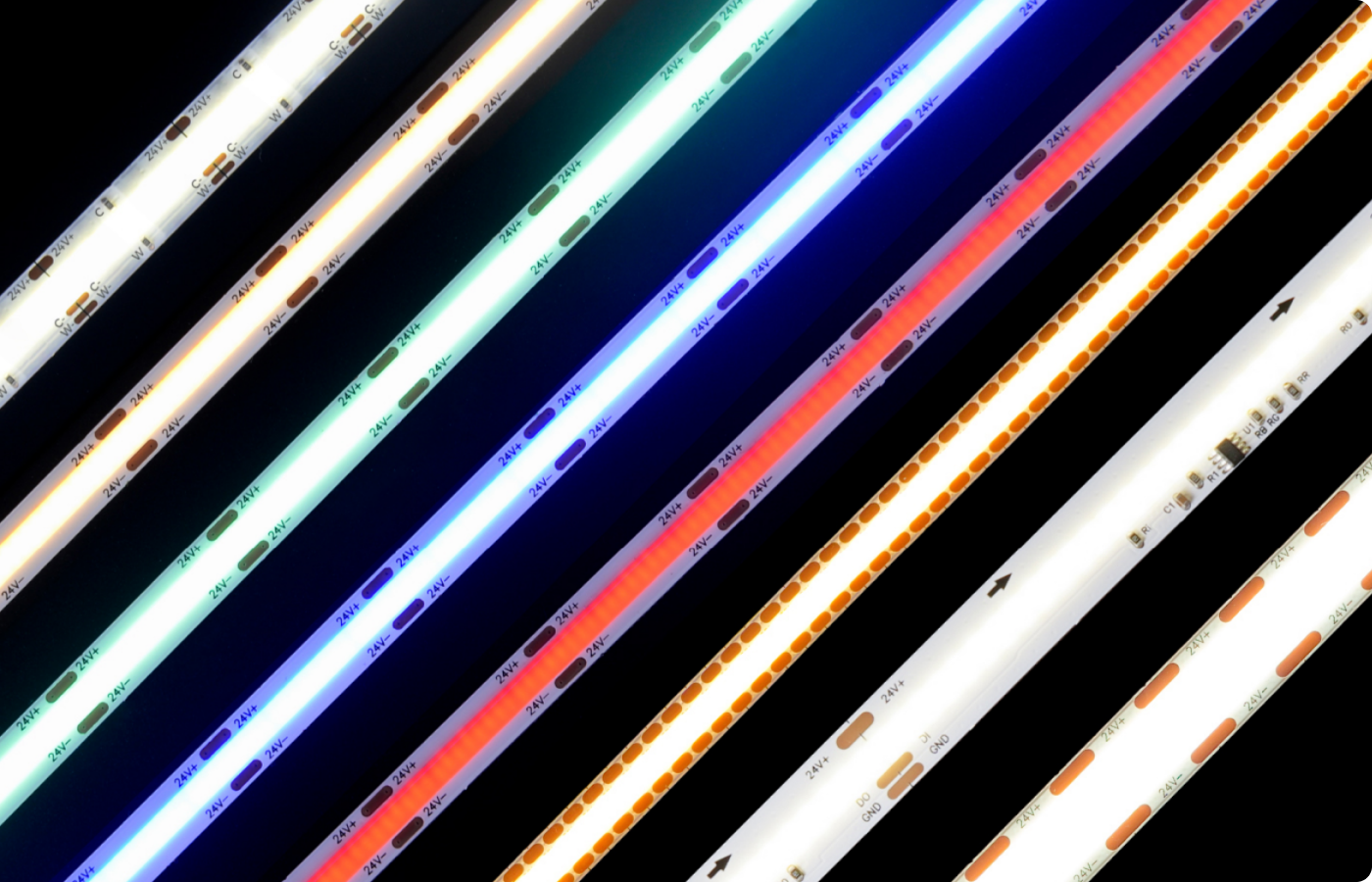

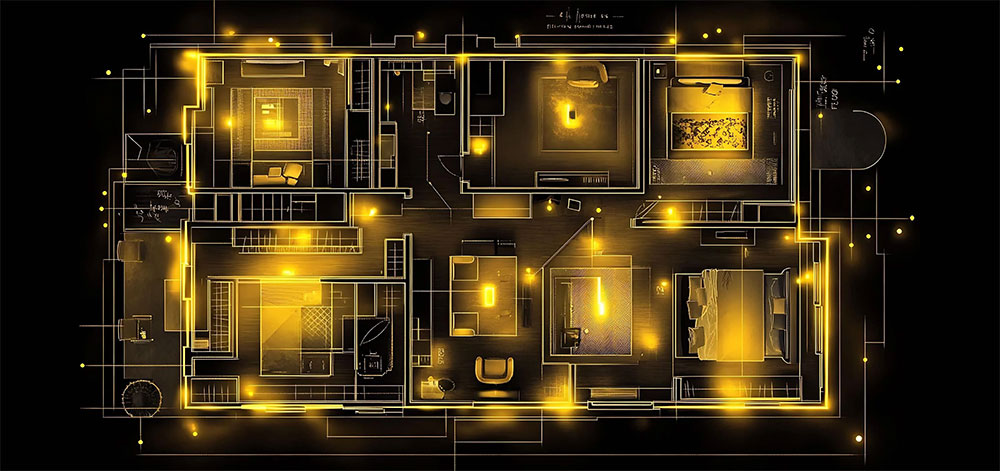

Nowadays, as we all know, modern lighting encompasses more about mood, aesthetics, energy efficiency, and smart integration in addition to just illuminate. LED tape lights, often referred to as LED strip lights, have emerged as one of the most practical, versatile, and necessary lighting solutions among all the lighting innovations in recent years. Their uses are more common than ever in 2025. They may be found in public infrastructure, commercial centres, hotels, residential buildings, architectural landmarks, and even underwater settings.

Why are they so essential? They have demonstrated good performance in both outdoor and indoor environments. Whether you are designing a fancy residence or setting mood lighting for a commercial place, LED tape lights are often an energy-efficient and flexible option. But with demand comes an explosion of supply, and under this booming LED tape lights market, there is always a challenge: the large number of manufacturers and suppliers. Across Asia, Europe, Australia and America, thousands of manufacturers and suppliers claim to offer the "best" LED tape lights. But we know not all of them are the best.

The performance, longevity, safety, and quality of LED tape lights actually differ greatly from brand to brand. This makes one question increasingly critical: how to choose the right LED tape light manufacturer and supplier in 2025?

What Makes a Good LED Tape Light Manufacturer and Supplier?

Knowing what makes a great LED tape light manufacturer or supplier different from a normal or bad one is essential for navigating this complicated industry. Here are the key features that a quality LED tape light manufacturer and supplier owns:

1. In-House R&D and Production Capabilities

It is crucial that a quality LED tape light manufacturer and supplier has its own independent R&D team and production line. This shows the ability of the manufacturer. They don't just have a simple assembly line, but also the LED packaging, SMD encapsulation, SMT surface mounting, neon extrusion, diffuser injection, and others. This indicates that they manage different production steps on their own and allow themselves to innovate, ensure product quality control at every step, and provide more flexibility options in custom solutions.

2. Product Quality

Knowing the quality of the product is perhaps the most effective and straightforward way to distinguish a good manufacturer. It includes how well the final product performs and how long it works in practical applications. You can tell the high quality of LED tape lights from these factors: brightness and efficacy, durability and lifespan, color consistency and accuracy, heat management, adhesive and connectors, and so on.

3. Quality Certifications and Compliance

Products with globally recognized certifications, such as CE, RoHS, UL, ETL, ISO9001, and LM-80 test reports for LED chips, are crucial to consider when choosing LED tape lights. These certifications offer independent confirmation that the items fulfill strict international criteria for performance, safety, and environmental responsibility, they are more than merely symbolic.

Assuring that items meet regulatory standards in many markets, certified products provide a guarantee of quality and dependability. In the end, selecting certified LED lighting is an essential first step toward installations that are secure, effective, and compliant.

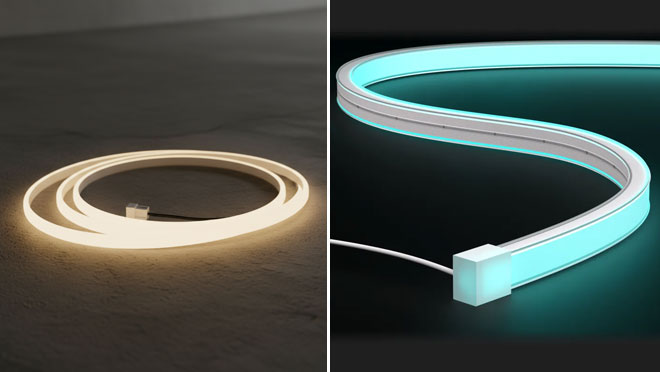

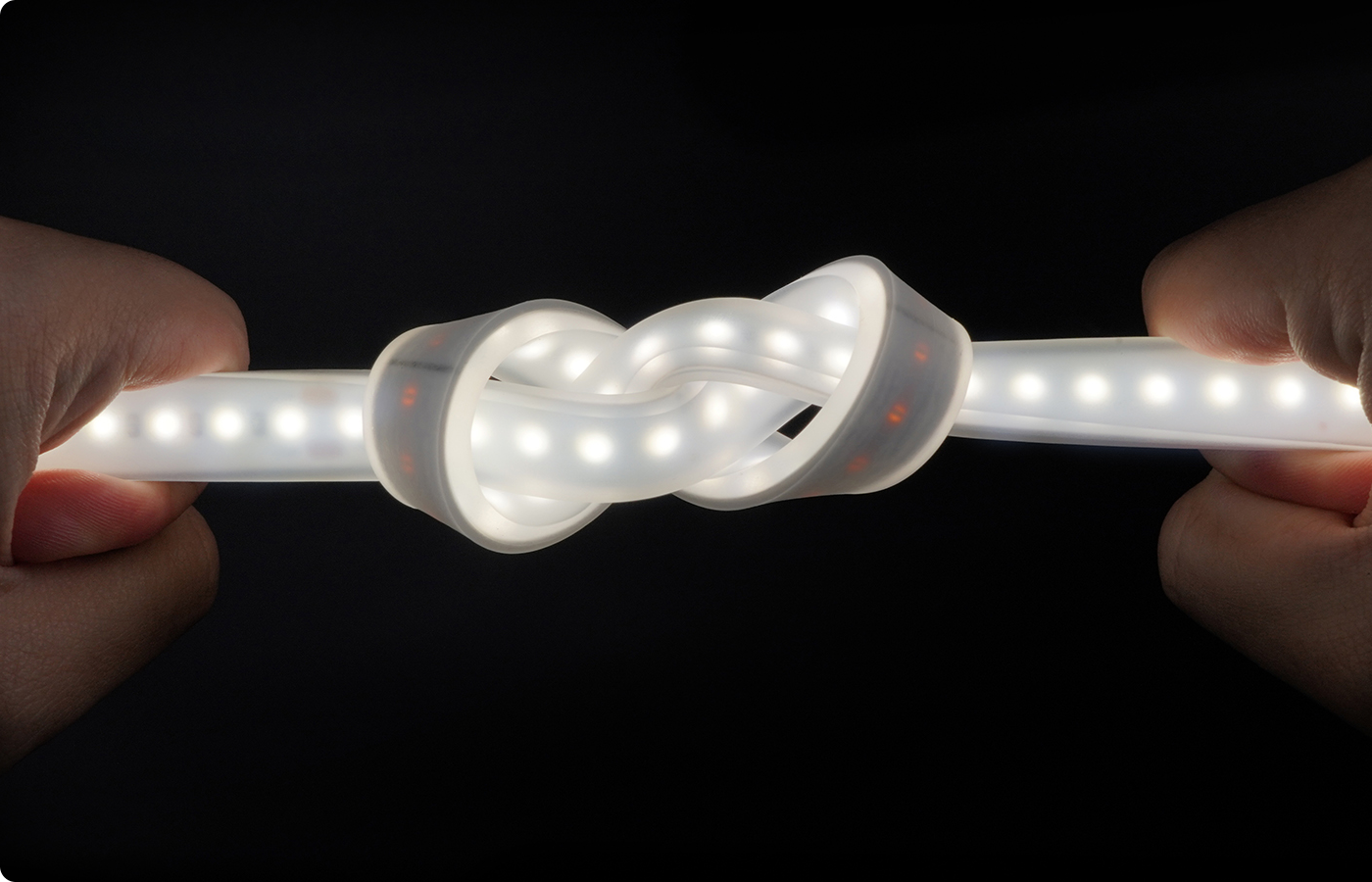

4. Advanced Encapsulation and Waterproofing Technology

Selecting LED tape light manufacturers that use cutting-edge protective technologies like completely enclosed silicone extrusion, TPU injection molding, or hybrid waterproofing techniques is crucial for outdoor or severe situations. The product's resistance against UV rays, salt spray, high temperatures, and yellowing over time is greatly increased by these production techniques.

What makes this significant? Because environmental stability and long-term durability are essential for outdoor LED applications. LED strips are more likely to fail early without adequate waterproofing and material protection, necessitating frequent replacements, higher maintenance expenses, and eventually unhappy customers. Purchasing weather-resistant, well-engineered items guarantees long-term dependability and constant performance.

5. Warranty Policy and Product Lifespan

A top LED tape light manufacturer may be identified by its dependable warranty policy and demonstrated product longevity. Prominent businesses show their faith in the quality of their products by frequently providing extended warranties of five to seven years.

Premium components like thick copper PCBs, high-performance branded LEDs, and long-lasting encapsulating materials like silicone or polyurethane are the foundation of this confidence. These components provide long-term dependability in tough settings in addition to improving performance. For what reason is this important? Longer warranties minimize failure risk, save maintenance costs, and provide peace of mind over time. They also demonstrate a manufacturer's dedication to longevity and customer satisfaction.

6. Comprehensive Product Range and Flexibility

An excellent supplier of LED tape lights offers a wide choice of products to suit various project requirements. This includes choices like pixel-addressable systems like DMX or DALI for dynamic lighting management, RGB/RGBW for vivid effects, tunable white for customizable ambiance, and high CRI for accurate color reproduction.

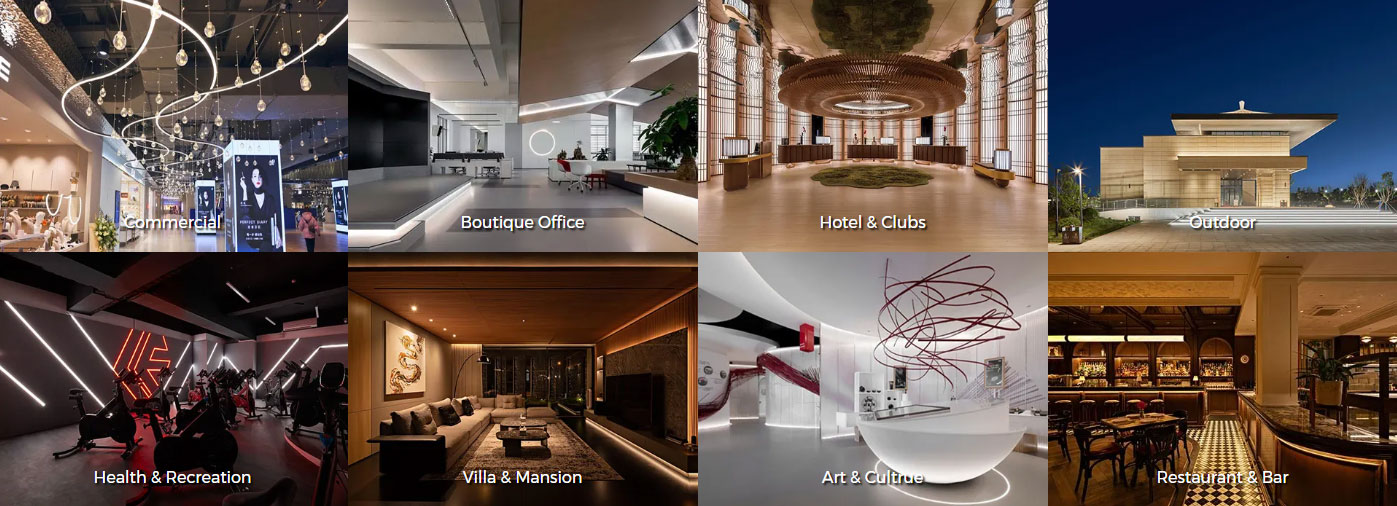

Their products usually range from ultra-narrow strips for confined locations to high-power versions for striking illumination, and from IP20 interior use to IP68 completely waterproof designs. Top vendors may also fulfill special demands for packaging, lengths, or forms. What makes this significant? A wide and adaptable product line guarantees the appropriate solution for every application by enabling you to meet specific design and technical requirements without sacrificing quality.

7. Strong Project Portfolio and Global References

It's crucial to consider if an LED tape light manufacturer has experience with large-scale lighting projects like hotels and buildings, as well as whether they have distributors or relationships across countries.

This type of worldwide presence and project engagement demonstrates not just technical proficiency but also the capacity to provide consistently high-quality work on a global basis. Why is this important? You may have more faith in a manufacturer's goods and services when they have a track record that demonstrates their expertise, dependability, and ability to fulfill high standards.

8. Technical Support and Service

Outstanding LED tape light manufacturers provide thorough professional support in addition to high-quality products. This includes access to DIALux or IES files for lighting simulation, prompt and efficient technical support, thorough installation instructions, and even specialized lighting design consultancy for certain projects.

What makes this significant? Time is saved, installation problems are reduced, and project execution runs more smoothly with dependable assistance before and after the sale. More significantly, it fosters enduring trust and collaboration between you and the supplier, increasing the effectiveness and success of subsequent partnerships.

Choosing the Right Manufacturer and Supplier - Introducing COLORS Lighting

Since we know the key features of a high-quality LED tape light manufacturer and supplier, the selection process becomes easier and clearer. Based on the above criteria, let’s present a standout manufacturer in the global lighting industry: COLORS Lighting.

Who is COLORS Lighting?

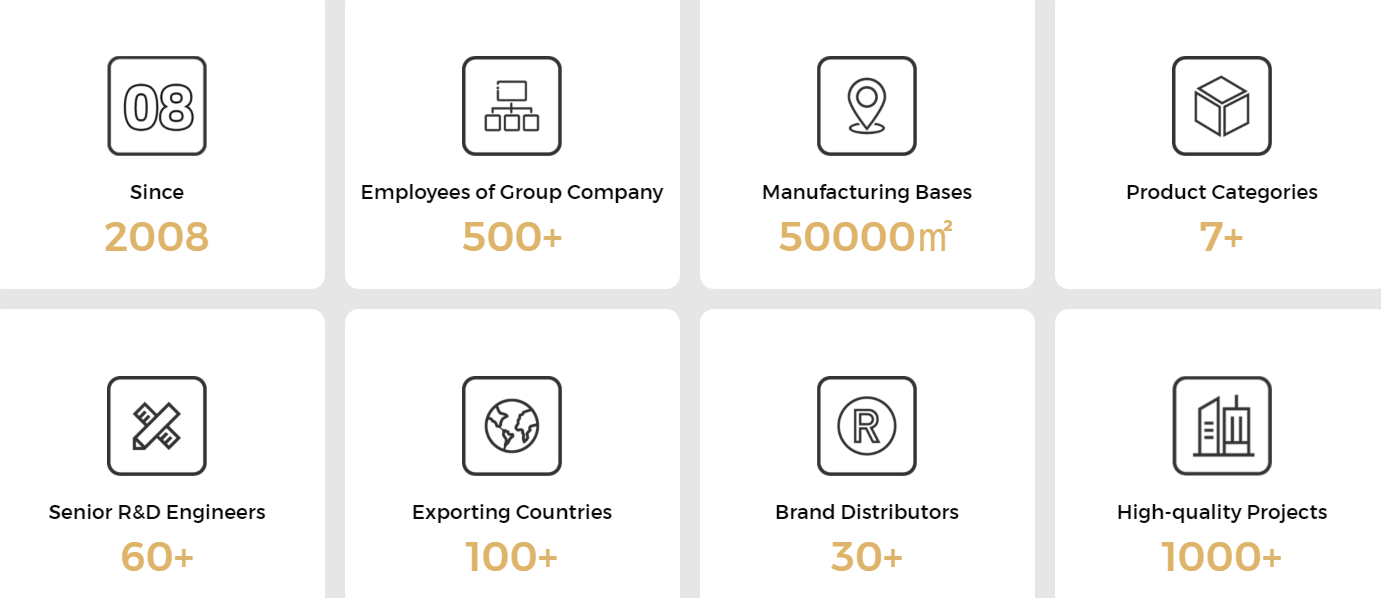

Founded in 2008, COLORS Lighting specializes in the research, development, and manufacturing of high-quality lighting products, which have been certified by all major national markets and are exported to more than 100 countries and regions worldwide.

COLORS Lighting has been a leading global brand in high-quality lighting, especially in linear lighting. Providing professional lighting solutions for residential, hotel, office, commercial, and outdoor spaces, and are committed to becoming a world-influential, innovative lighting enterprise and creating an ideal lighting space for the world.

Why Choose COLORS Lighting?

COLORS Product Concepts

COLORS Lighting is always customer-oriented and adheres to the design concept of "Minimalism, Innovation, and Experience First", to bring customers "Modular, Professional, and Intelligent" lighting products and "Innovative, Flexible, Easy to Install" user experience, and provide "In-depth Flexible Customization" service and "One-stop Procurement" solutions.

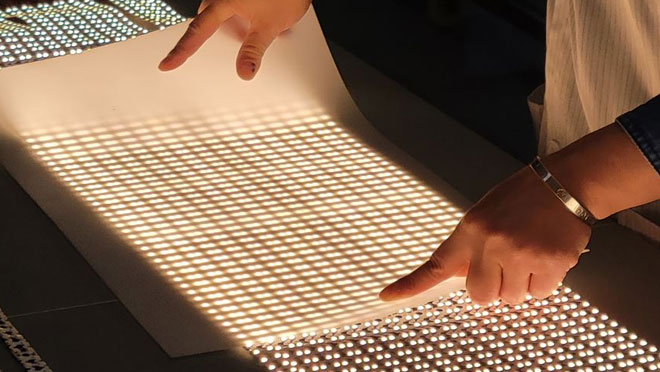

Master the Core Technology of Light Color

COLORS Lighting masters the three mainstream LED light source independent encapsulation technology capabilities, to provide customers with various international light color standards, and different light quality products.

R&D Strength

COLORS Lighting's R&D team has over 60 core technical personnel, with key members primarily graduating from top-tier universities.

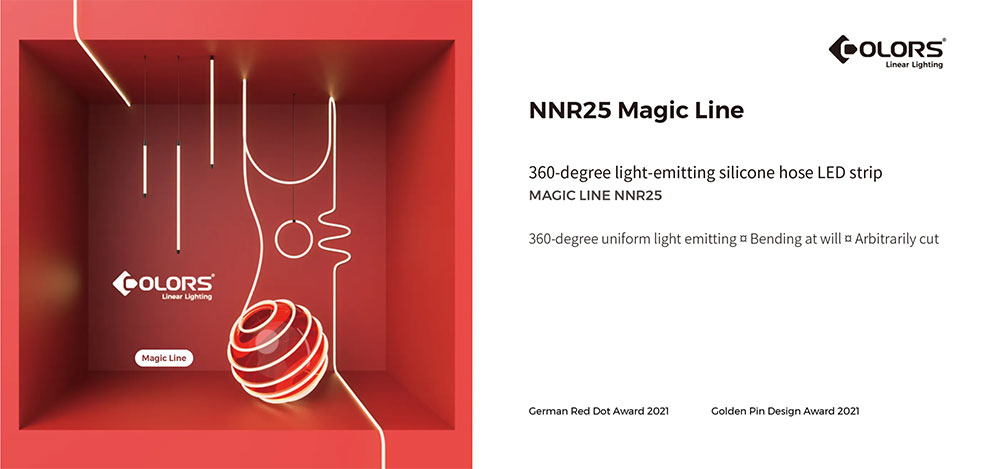

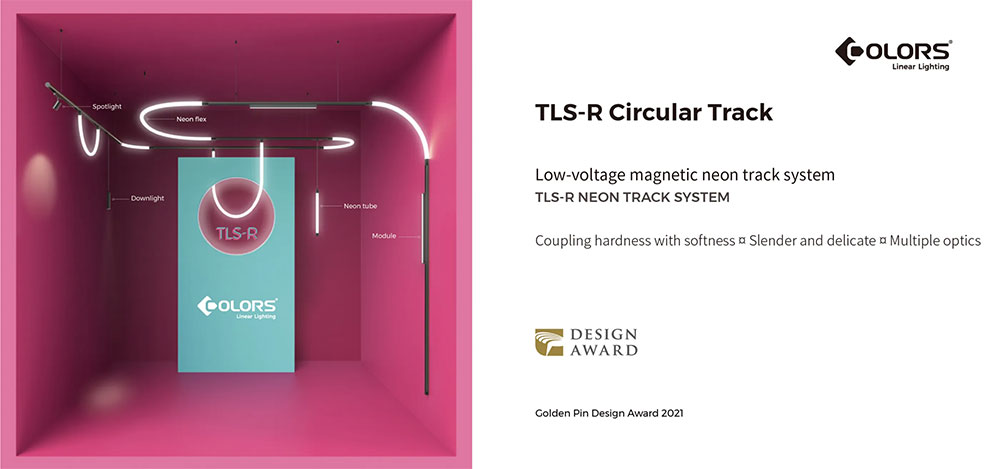

COLORS Lighting sticks to independent R&D and intellectual property management. Qualified for the title of National High-tech Enterprise, and repeatedly gained international design awards, inclusive of IF, IDEA, RED DOT, and GOLDEN PIN, etc.

Core Competency

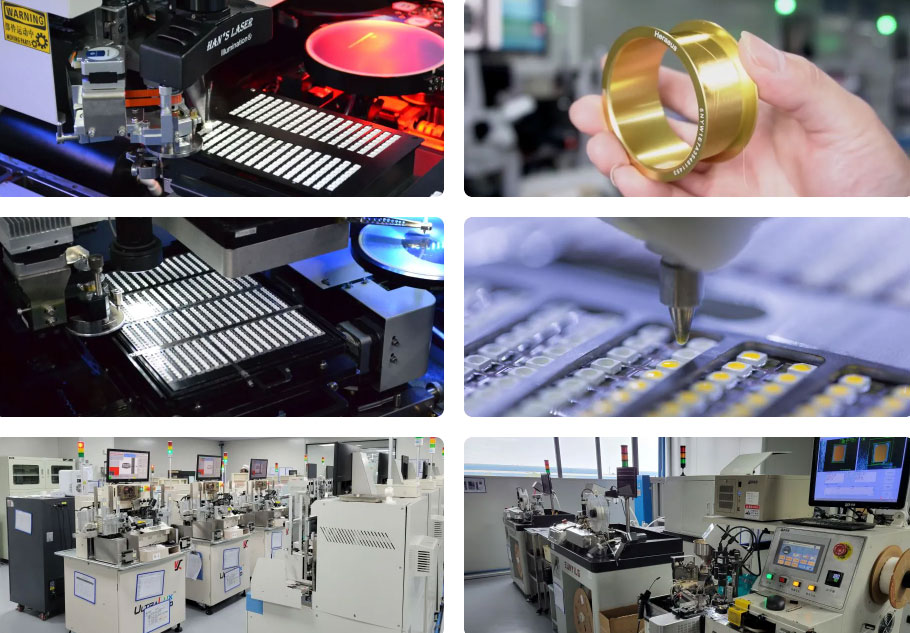

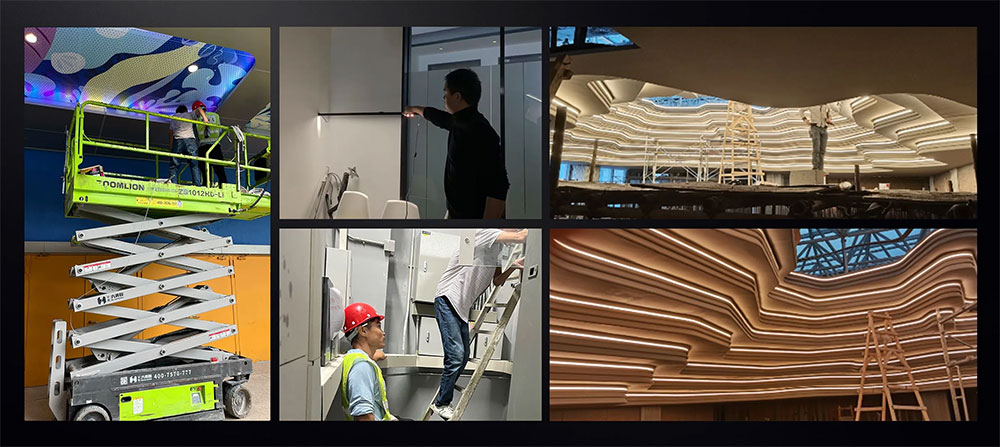

COLORS Lighting operates manufacturing bases in Yangzhou and Jiangmen, the production area exceeds 50,000 square meters, with the whole flow in manufacturing production capabilities for LED strips light source, and linear lights, supporting efficient, flexible customization and rapid delivery. The Yangzhou Light Source manufacturing base possesses comprehensive production capabilities for the whole light source, including LED encapsulation, SMT surface mounting, automatic welding, a full range of waterproofing, neon extrusion, and others.

COLORS Lighting owns an independent production throughout the entire supply chain. And it operates a complete, high-quality production line covering SMD Encapsulation, SMT Surface Mounting, Neon Extrusion, Hardware Spraying, and Finished Product Assembly.

SMD Encapsulation

Core Component of LED Strips & Neon Strips

Gold Wire Inside

Enhanced Bracket

Strict Binning Management

Customization Support

Dedicated Only for Self-use

SMT Surface Mounting

Highly Automated Production

Precisely Match Resistance Based on the LED's VF to Effectively Control Product Power Consumption

100% QC at Every Step of the Production Process

Capacity up to 40,000m Per Day

R2R & COF Production Line

Highly Automatic Production with R2R Tech

2 Lines of COF Strip Production

LED STRIP Production Line

Auto-soldering & Manual Soldering

On-site Support Quickly Solves Quality Issues

QC Inspection at Every Step of the Production Process

Capacity up to 40,000m Per Day

NEON STRIP Production Line

5 Extrusion Production Lines

Cutting Point Visible Extrusion Tech

Anti-static Surface Processing Tech

Capacity up to 14,000m Per Day

Warehousing Shiping

Forklift Operation in Warehouses

WMS System Storage Management

Customers Determine Logistics Information

Delivery to Global Customers through Logistics Companies

Quality Assurance

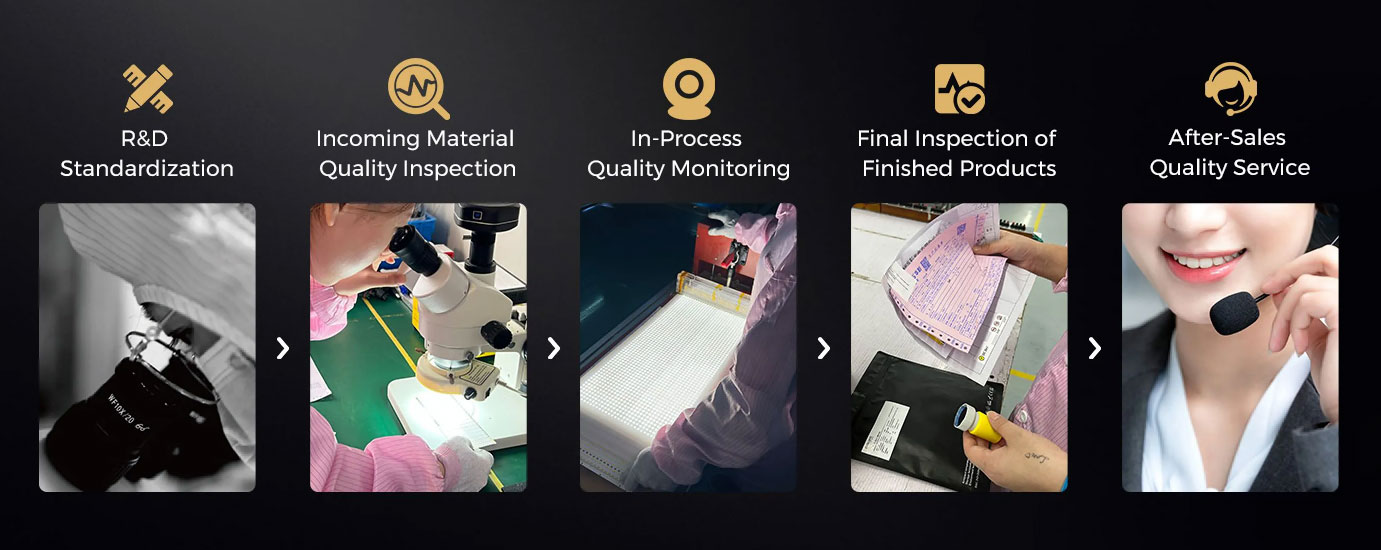

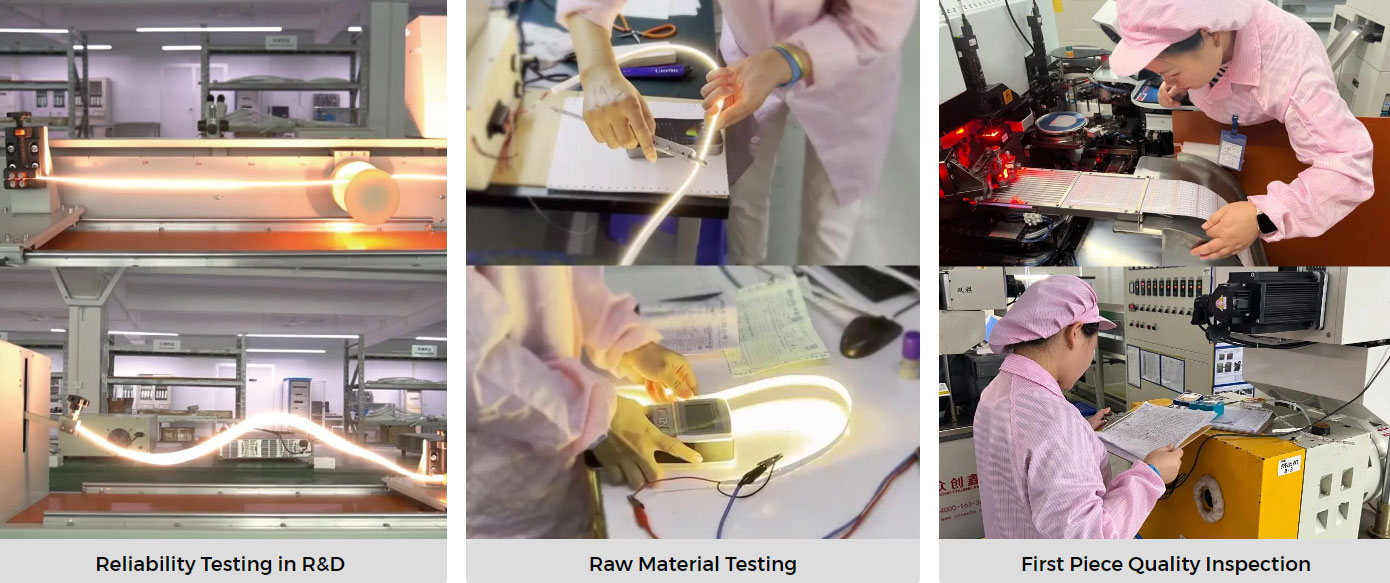

COLORS Lighting implements comprehensive quality control across five key stages: Pre-production R&D, Incoming Material Inspection, In-process Production Control, Finished Product Inspection, and After-sales Service.

100% First Piece Approval

Strict R&D standards are enforced, with on-site Incoming Quality Control (IQC) inspections, and trial production is conducted before mass production.

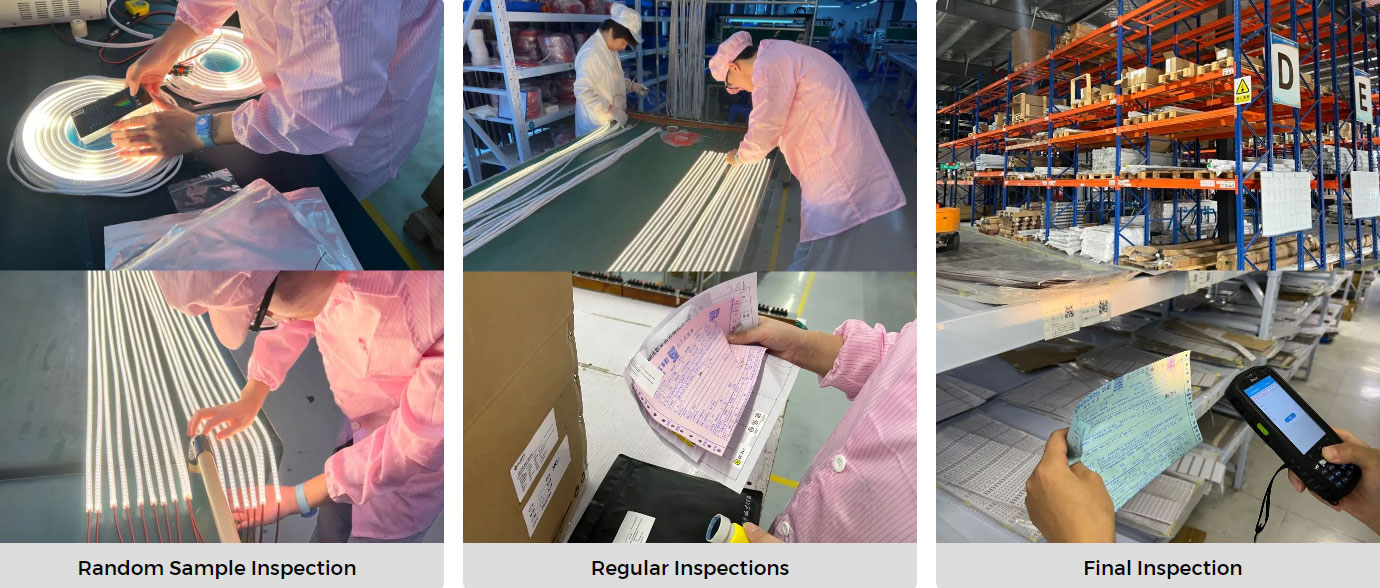

In-process Sampling Inspection & Pre-shipment Final Inspection

All products undergo sampling inspections, scheduled patrol inspections every two hours, and a final inspection before shipment.

COLORS-LAB

Established in 2014, the lab covers 460m² and complies with ISO17025 standards. It features 11 functional zones and a full complement of test instruments.

Support for Certificates & Reports

Support for Internal Quality Assurance

Define Product Quality Standard

Raw Material Recognition

Finished Product Comprehensive Test

Support for Internal Quality Assurance

Define Product Quality Standard

Raw Material Recognition

Finished Product Comprehensive Test

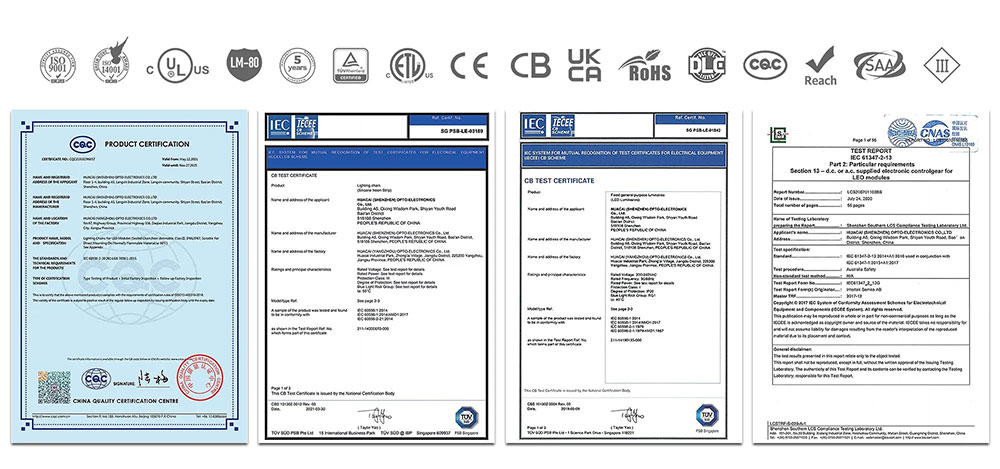

Quality Certification System

ISO9001 Quality System and ISO14001 Environmental System Certifications for Manufacturer Bases. All products have passed tests of third-party authoritative laboratory institutions and have obtained multiple quality certifications, inclusive Of COC, CE, CB, REACH, ROHS, UL, ETL, SAA, TUV, LM-80, etc. required by various countries and regions.

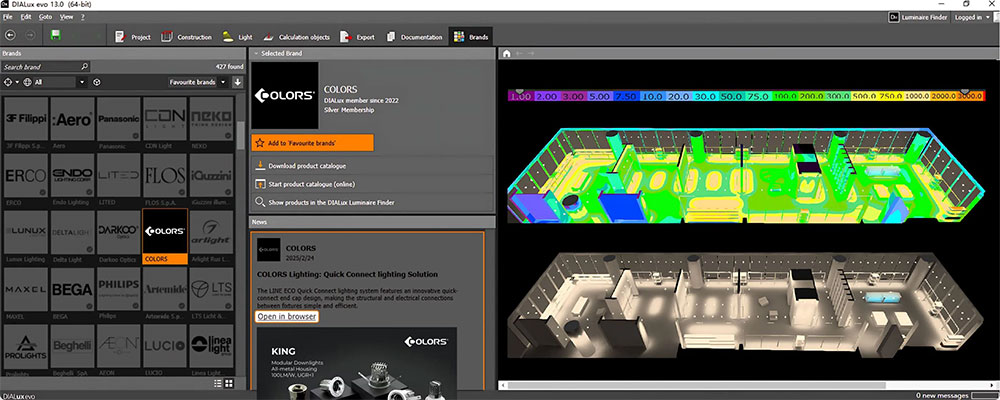

Silver Member of DIALux

COLORS is a Silver Member of DIALux. All product 3D models and IES files are readily available for immediate use.

Lighting Design Support

COLORS Lighting has a professional lighting design team, key projects to provide pre-design planning, mid-term selection simulation, post-installation and commissioning of professional support.

On-site Technical Service

For key projects, we can cooperate with designers and engineers to deepen the pre-sale product application program.

1000+ High Quality Projects

Over the past 20 years, COLORS Lighting has successfully implemented over 1,000 high-quality lighting projects around the world with partners such as lighting designers, service providers and distributors. In the past decade, we have held CCP (a global case collection competition) every autumn to showcase the latest lighting design and product application achievements, promote communication, inspire each other, fight for its mission, and strive towards its vision!

Conclusion

Modern architecture and lifestyle continue to rely heavily on LED tape lights as lighting continues to develop into a fusion of sustainability, design, and functionality. In 2025, however, selecting the best manufacturer and supplier is more crucial than ever due to the abundance of options available on the market.

In this context, COLORS Lighting is a standout partner because it combines state-of-the-art technology, elegant design, and unwavering dependability. Distributors, designers, contractors, and end users may all benefit from COLORS' lighting solutions, which make spaces come to life.

Still have any questions about the products or need further clarification? Please don't hesitate to reach out to us and let us help you with your lighting projects!

COLORS Lighting, Colorful Life!