Blog

PU vs Silicone LED Neon Flex Lights: Which one is Better?

PU vs Silicone LED Neon Flex Lights: Which one is Better?

Joyce Alva.UpdatedDecember 5, 2025|9 mins Read

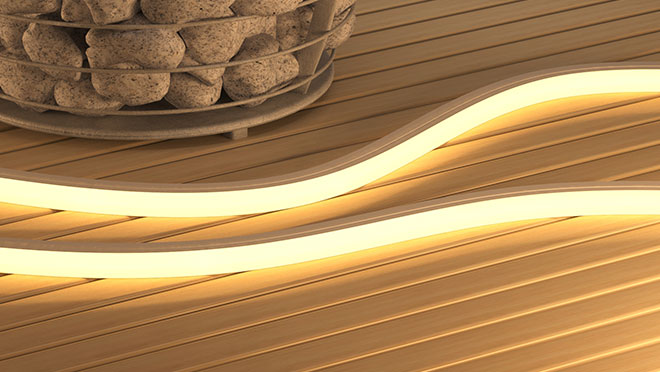

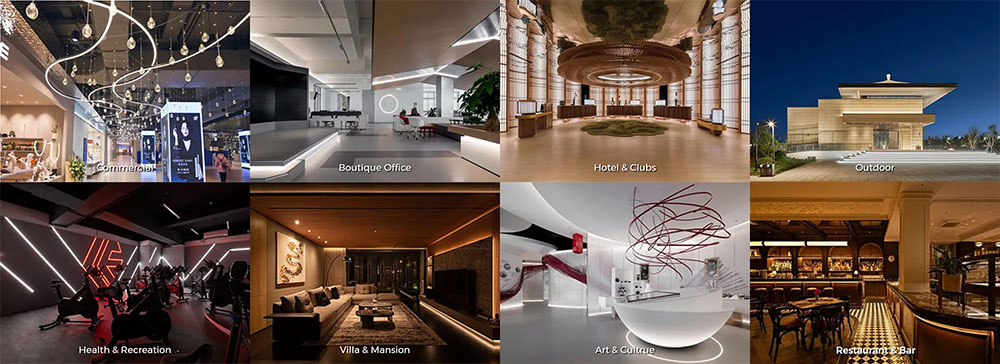

It is nearly impossible today to walk through a modern city, commercial district, or even a contemporary household without encountering LED neon flex lights. These versatile lighting solutions have seamlessly blended into our daily environments, transforming the way we perceive and interact with illuminated spaces.

Whether outlining a building façade, guiding pathways in a landscape project, enhancing interior ambient lighting, or creating eye-catching signage for brands, LED neon flex lights offer a combination of aesthetic elegance and practical functionality.

In urban centers, LED neon flex lines are commonly seen running along the edges of high-rise buildings, adding a dynamic night-time identity to city skylines. This kind of lighting not only enhances architectural form but also improves visibility, providing a subtle mix of artistic expression and safety.

In commercial spaces such as retail stores, restaurants, shopping malls, and entertainment venues, LED neon flex helps set the tone—warm and welcoming, bold and brand-centric, or futuristic and immersive. Designers use them to create subtle ceiling coves, under-shelf highlights, window frames, and even large-scale decorative sculptures.

Among the many materials used for LED neon flex tubes, PU (polyurethane) and silicone stand out as two of the most common and widely discussed options. But with the market filled with different LED neon flex products - each claiming durability, high brightness, and flexibility, so how do you choose between PU and silicone?

Different Types of LED Neon Flex: PU vs Silicone

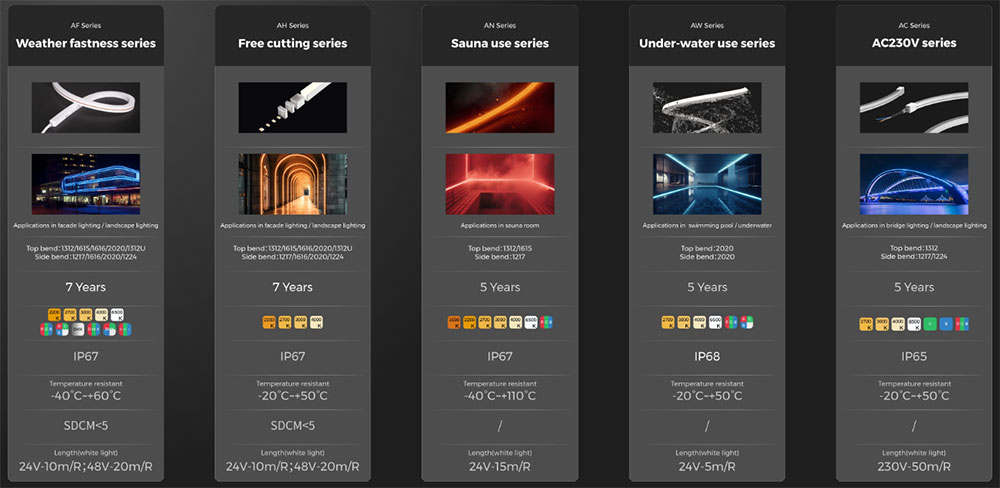

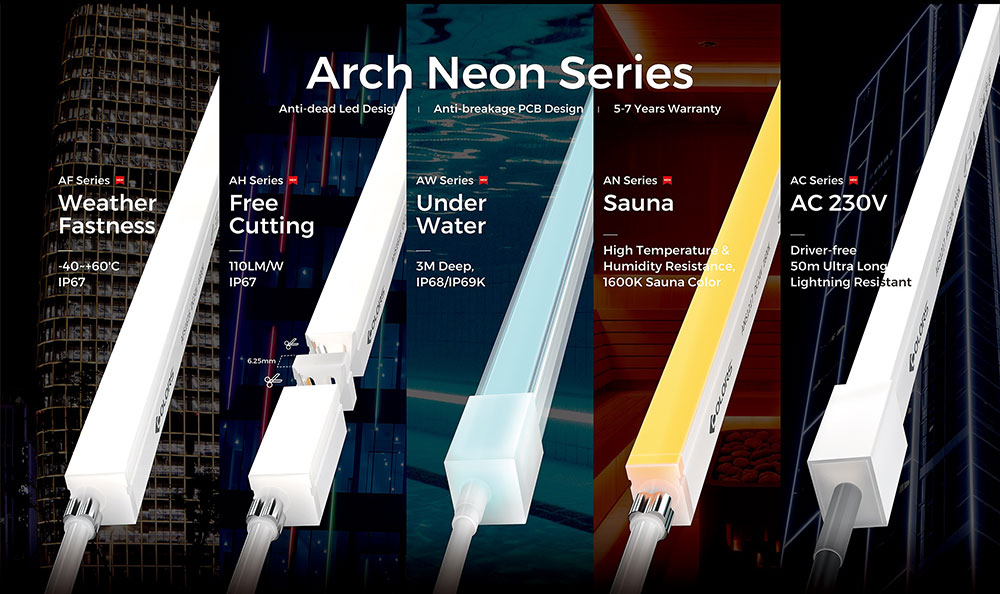

LED neon flex lights come in various forms based on application, luminance, color rendering, internal LEDs, beam type, waterproof level, and, most importantly, material composition. Among the materials used to manufacture the outer diffused housing, PVC, PU, and silicone are the three most popular options.

PVC (polyvinyl chloride) is widely used due to its low cost and acceptable durability, making it popular for indoor and decorative applications. However, PVC has limitations in UV resistance, bending properties, and long-term outdoor performance.

This is where PU and silicone neon flex lights enter the picture, raising the standard of quality for professional lighting applications.

PU (polyurethane) and silicone neon flex tubes are now considered premium materials due to their advanced mechanical and weather-resistant properties. Both offer better flexibility, higher environmental tolerance, greater longevity, and a more refined lighting diffusion effect compared to PVC. Because of this, industries such as architecture, hospitality, outdoor landscape design, and entertainment often rely on PU or silicone neon flex lights to meet high-performance requirements.

However, PU and silicone are quite different in their characteristics. Each material excels in certain scenarios and offers specific advantages. Understanding these differences is essential for choosing the right product for a long-lasting lighting installation.

Before we compare them directly, let's take a deeper look at what PU neon flex and silicone neon flex lights actually are, how they are made, and what makes them unique.

What Are PU LED Neon Flex Lights? Features, Benefits & Applications

PU LED neon flex lights are constructed using a polyurethane jacket that encapsulates the LEDs and internal components. PU is a highly versatile polymer widely used in products that require toughness, elasticity, and resistance to environmental stress. In lighting applications, PU is appreciated for its superior tensile strength, exceptional resilience, and clear, glossy finish.

1. Material Properties of Polyurethane

Polyurethane is known for a combination of softness and hardness. It can be engineered to be either very flexible or semi-rigid, depending on the product requirements. This makes PU neon flex lights suitable for various designs, especially where mechanical strength and exterior toughness are vital.

Its unique properties include: high elasticity, excellent tensile and tear strength, abrasion resistance, impact resistance, chemical resistance.

These attributes allow PU LED neon flex to withstand environments that may cause damage to other materials.

2. Features of PU LED Neon Flex Lights

2.1 High Durability and Toughness

PU neon flex lights boast a high level of mechanical strength. They resist impacts, stretching, and tearing better than many silicone products. This makes them ideal for areas where the lighting strip might be touched, pressed, bent frequently, or exposed to potential physical damage.

PU neon flex lights boast a high level of mechanical strength. They resist impacts, stretching, and tearing better than many silicone products. This makes them ideal for areas where the lighting strip might be touched, pressed, bent frequently, or exposed to potential physical damage.

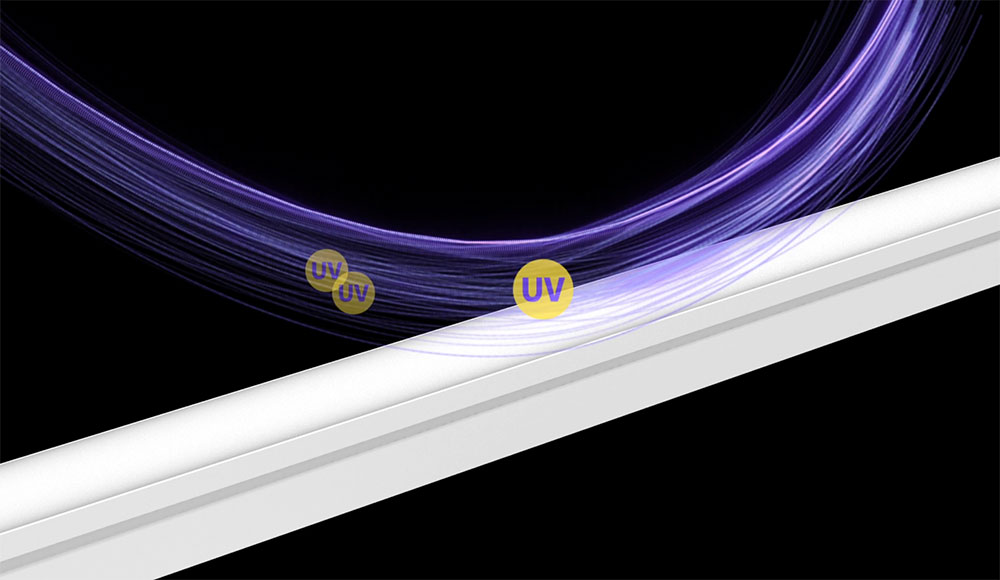

2.2 Strong UV Resistance

Polyurethane possesses excellent resistance to ultraviolet radiation. This prevents yellowing, cracking, or degradation even after years of continuous outdoor exposure. Therefore, PU neon flex lights maintain their clarity and color stability longer than several other materials.

2.3 Superior Chemical and Oil Resistance

PU is widely used in industrial environments because of its resistance to oils, fuels, chemicals, and corrosive materials. For this reason, PU LED neon flex lights are commonly installed in petrol stations, factories, and other areas where chemical interaction may occur.

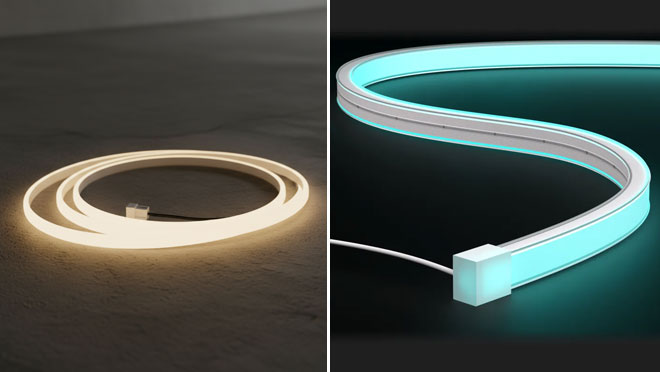

2.4. Smooth, Glossy Surface Finish

PU neon flex tubing tends to have a sleek, polished surface that reflects light in a refined manner. This gives designers a clean and modern lighting appearance, ideal for high-end commercial applications.

2.5 Better Performance in Cold Temperatures

PU maintains its flexibility and elasticity even in extremely low temperatures. This makes PU neon flex suitable for cold regions, winter climates, refrigerated storage areas, and outdoor installations requiring long-term stability.

2.6 Fire Resistance (Depending on Grade)

Some grades of PU offer excellent fire-resistant properties, allowing manufacturers to achieve compliance with safety certifications required for public spaces and specialized environments.

2.7 High Color Stability for Milky Diffusion

PU materials maintain their milky, uniform light diffusion over time, ensuring stable color and brightness output.

3. Common Applications of PU LED Neon Flex

PU LED neon flex lights are preferred in environments requiring mechanical durability, UV resistance, and chemical protection, including: architectural outlines of buildings, outdoor signage and branding, public installations and landmarks, petrol stations and industrial zones, areas with frequent human contact or high foot traffic, commercial façades, transport hubs, bridges, tunnels, cold-weather regions and refrigerated spaces.

With strong weather protection and long service life, PU LED neon flex lights deliver robust performance across demanding outdoor and industrial applications.

4. What Are Silicone LED Neon Flex Lights? Features, Benefits & Applications

Silicone LED neon flex lights use silicone rubber as their exterior material, offering an unmatched combination of flexibility, temperature tolerance, food-grade safety, and optical purity. Silicone neon lights are widely regarded as the premium standard for high-end lighting projects due to their durability, softness, and optical clarity.

4.1 Material Properties of Silicone

Silicone is an elastomer with exceptional temperature stability, chemical inertness, and environmental resistance. It maintains its physical and optical properties over a wide range of conditions, making it one of the most stable polymers available for lighting applications.

Key characteristics include: extreme flexibility, non-yellowing clarity, soft and smooth to the touch, high resistance to heat and cold, anti-corrosion and anti-UV properties.

These qualities make silicone LED neon flex lights a popular choice for professional-grade LED lighting.

4.2 Features of Silicone LED Neon Flex Lights

4.2.1. Best-in-Class Flexibility and Bending Performance

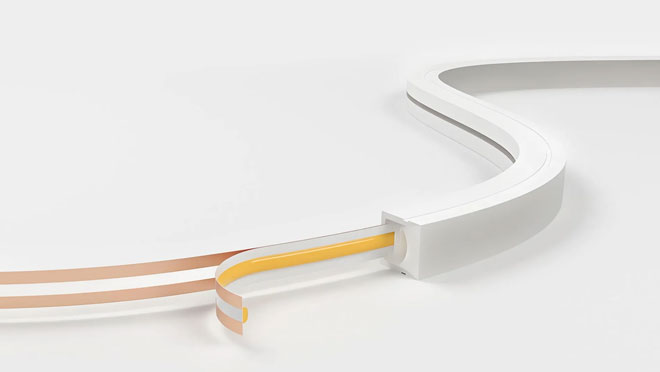

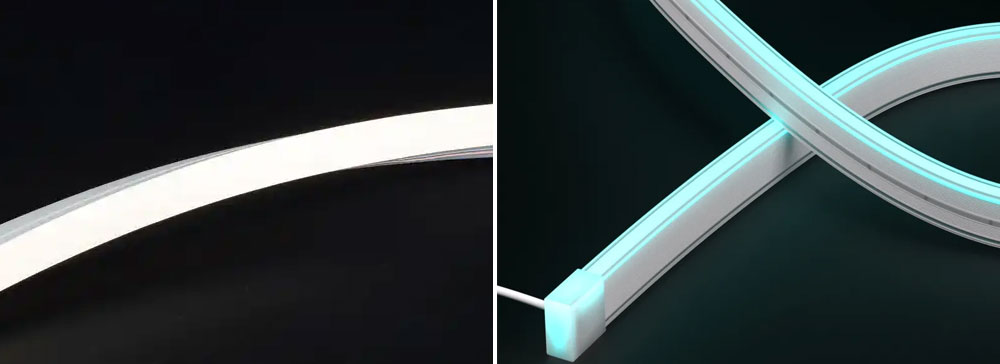

Silicone neon flex is significantly more flexible than PU. The material bends effortlessly without stress marks, making it ideal for curves, corners, and artistic shapes. Designers prefer silicone for projects requiring smooth, continuous lighting contours.

Silicone neon flex is significantly more flexible than PU. The material bends effortlessly without stress marks, making it ideal for curves, corners, and artistic shapes. Designers prefer silicone for projects requiring smooth, continuous lighting contours.

4.2.2. Excellent Heat Resistance

Silicone can withstand long-term exposure to high temperatures without deformation or discoloration. This is useful for powerful neon lights, RGB or RGBW systems, and high-density LED setups.

4.2.3. Unmatched UV Stability

Silicone is naturally UV-resistant and does not yellow easily. This ensures optimal optical performance even after years under harsh sunlight. For tropical climates or strong sunlight exposure, silicone is often the superior choice.

4.2.4. High Chemical, Corrosion, and Saltwater Resistance

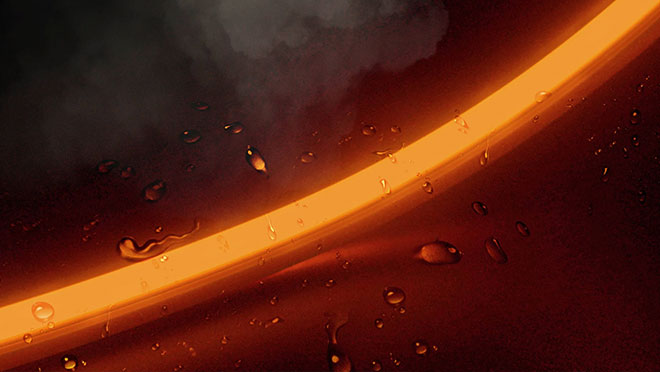

Silicone's inertness makes it suitable for coastal regions, swimming pools, humid environments, and even underwater applications. It does not degrade when exposed to salt, chlorine, or moisture.

4.2.5. Softer Material for Premium Visual Appeal

The smooth, matte, and soft texture of silicone neon flex provides a refined, modern look. Its diffusion effect tends to be more uniform, delivering continuous, dot-free illumination.

4.2.6. Wide Temperature Range (-50°C to 200°C)

Silicone maintains its flexibility and structure in extremely hot or cold environments, surpassing both PVC and PU in stability.

4.2.7. Long Lifespan and Low Maintenance

Silicone's resistance to aging, cracking, and corrosion gives it exceptional longevity. This leads to reduced maintenance costs over its service life.

4.2.8. Great Waterproofing and Sealing Performance

Silicone is commonly used for IP67, IP68, and even IP69K neon products. Its natural waterproofing properties make it the preferred material for underwater neon flex lights and severe weather environments.

4.3 Common Applications of Silicone LED Neon Flex

Silicone LED neon flex lights are used in environments requiring maximum flexibility, optical purity, waterproofing, and long-term UV stability, including: luxury residential lighting, hospitality and commercial interiors, architectural façades requiring complex curves, underwater or poolside installations, marine and coastal lighting, skylines and building profiles in high UV regions, artistic light sculptures, theme parks and entertainment venues.

Silicone LED neon flex lights are used in environments requiring maximum flexibility, optical purity, waterproofing, and long-term UV stability, including: luxury residential lighting, hospitality and commercial interiors, architectural façades requiring complex curves, underwater or poolside installations, marine and coastal lighting, skylines and building profiles in high UV regions, artistic light sculptures, theme parks and entertainment venues.

With unmatched flexibility and stability, silicone neon flex shines in projects emphasizing aesthetics, creativity, and longevity.

5. PU vs Silicone LED Neon Flex: Which One Is Better and Why?

Now that we understand the characteristics of both PU and silicone neon flex lights, it is time to compare their performance across various perspectives and determine which material is more suitable for different applications.

5.1 Flexibility and Bend Radius

Silicone neon flex is generally more flexible than PU. It can bend smoothly without stress whitening or deformation, making it ideal for curves, S-shapes, circular designs, and complex installations. PU is flexible but tends to be slightly stiffer and less suitable for tight bends.

Silicone neon flex is generally more flexible than PU. It can bend smoothly without stress whitening or deformation, making it ideal for curves, S-shapes, circular designs, and complex installations. PU is flexible but tends to be slightly stiffer and less suitable for tight bends.

Winner: Silicone

5.2 Weather Resistance and Longevity

Both PU and silicone offer superior UV resistance compared to PVC, but silicone has the advantage of maintaining optical clarity and flexibility longer. Over long-term outdoor exposure, silicone resists yellowing, hardening, and cracking better than PU.

Winner: Silicone

Both PU and silicone offer superior UV resistance compared to PVC, but silicone has the advantage of maintaining optical clarity and flexibility longer. Over long-term outdoor exposure, silicone resists yellowing, hardening, and cracking better than PU.

Winner: Silicone

5.3 Mechanical Strength and Toughness

This is where PU outperforms silicone. PU's high tensile strength and abrasion resistance make it the better choice for environments with physical impact risk or mechanical wear.

Winner: PU

This is where PU outperforms silicone. PU's high tensile strength and abrasion resistance make it the better choice for environments with physical impact risk or mechanical wear.

Winner: PU

5.4 Chemical Resistance

Both materials have good chemical resistance, but silicone is inert and performs better under saltwater, chlorine, and corrosion-heavy environments. PU is better against oils and industrial chemicals.

Both materials have good chemical resistance, but silicone is inert and performs better under saltwater, chlorine, and corrosion-heavy environments. PU is better against oils and industrial chemicals.

Winner: Depends on the environment

Silicone for saltwater, chlorine, and moisture-heavy environments.

PU for oils and industrial chemicals.

PU for oils and industrial chemicals.

5.5 Heat Resistance

Silicone has a much wider temperature tolerance than PU. It remains stable even under high heat generated during long-term operation or in hot climates.

Winner: Silicone

Silicone has a much wider temperature tolerance than PU. It remains stable even under high heat generated during long-term operation or in hot climates.

Winner: Silicone

5.6 Surface Finish

PU typically has a shinier, glossier finish that looks premium in modern commercial environments. Silicone has a soft, matte appearance that diffuses light more uniformly.

Winner: Depends on aesthetic preference

PU typically has a shinier, glossier finish that looks premium in modern commercial environments. Silicone has a soft, matte appearance that diffuses light more uniformly.

Winner: Depends on aesthetic preference

5.7 Waterproofing and Underwater Applications

Silicone is inherently waterproof and ideal for underwater neon flex (pools, fountains, marine projects). PU can be waterproof but is less suitable for long-term underwater exposure.

Winner: Silicone

Silicone is inherently waterproof and ideal for underwater neon flex (pools, fountains, marine projects). PU can be waterproof but is less suitable for long-term underwater exposure.

Winner: Silicone

5.8 Cost and Budget Consideration

PU is generally more cost-effective than silicone while still offering excellent performance. Silicone, being a premium material, usually costs more due to its optical purity and stability.

Winner: PU for budget projects

PU is generally more cost-effective than silicone while still offering excellent performance. Silicone, being a premium material, usually costs more due to its optical purity and stability.

Winner: PU for budget projects

Which One Is Better Overall?

If we consider all factors—flexibility, stability, longevity, outdoor performance, waterproofing, and aesthetics—silicone LED neon flex is generally considered better for most applications, especially architectural, residential, artistic, and outdoor projects.

However, PU LED neon flex is better when mechanical toughness, abrasion resistance, and cost-effectiveness are the priorities, such as in industrial environments, public spaces, and high-contact areas.

The choice ultimately depends on what matters most for your lighting project.

Conclusion

PU LED neon flex and silicone LED neon flex each bring valuable advantages to modern lighting design. PU neon flex lights are durable, mechanically strong, and cost-effective, making them ideal for industrial, commercial, or high-contact environments. Silicone neon flex lights offer superior flexibility, optical purity, weather resistance, and long-term stability, making them the go-to choice for architectural façades, artistic lighting installations, underwater lighting, luxury interiors, and high-end design projects.

Instead of asking which material is universally "best", the more important question is: Which material is best for your specific project requirements?

If your priority is toughness, affordability, or resistance to heavy mechanical stress, PU LED neon flex is the appropriate choice.

If you need premium lighting quality, complex bending shapes, high UV or heat resistance, or underwater reliability, silicone LED neon flex is the superior option.

Both materials have unique strengths and have contributed to the widespread adoption of LED neon flex lights in projects across the world. By understanding their differences, you can confidently choose the right neon flex material for projects that will stand the test of time, environment, and design demands.