Blog

Underwater LED Strip for Fountains and Water Features

Underwater LED Strip for Fountains and Water Features

Joyce Alva.UpdatedDecember 12, 2025|8 mins Read

Water is one of the most powerful elements in design. From large public fountains to quiet residential ponds, from landscaped waterfalls to artistic water walls - water brings life, movement, and emotion into architectural spaces. But when water meets light, especially underwater light, the result becomes magical. Light adds depth, dimension, and drama. It reveals textures, highlights motion, and creates artistic reflections that transform ordinary water features into dynamic visual experiences.

Among all lighting technologies used for water features today - spotlights, underwater projectors, wall washers - underwater LED strip lights have become one of the most innovative, flexible, and aesthetically appealing options. They are slim, versatile, energy-efficient, and capable of creating continuous lines of light that feel natural inside water.

However, not all LED strips are suitable for underwater use, and choosing the wrong product can lead to safety issues, water ingress, early failure, color fading, or unnecessary maintenance costs.

This comprehensive guide explores everything you need to know about underwater LED strips for fountains and water features, including lighting principles, technical standards, waterproof technologies, applications, installation methods, and how to choose a reliable manufacturer.

1. Why Use Underwater LED Strip Lights in Water Features?

When designing water-based architectural elements, lighting is not just decoration - it changes the entire perception of the space. LED strips bring several unmatched advantages:

1.1 Ultra-Flexible Lighting Effects

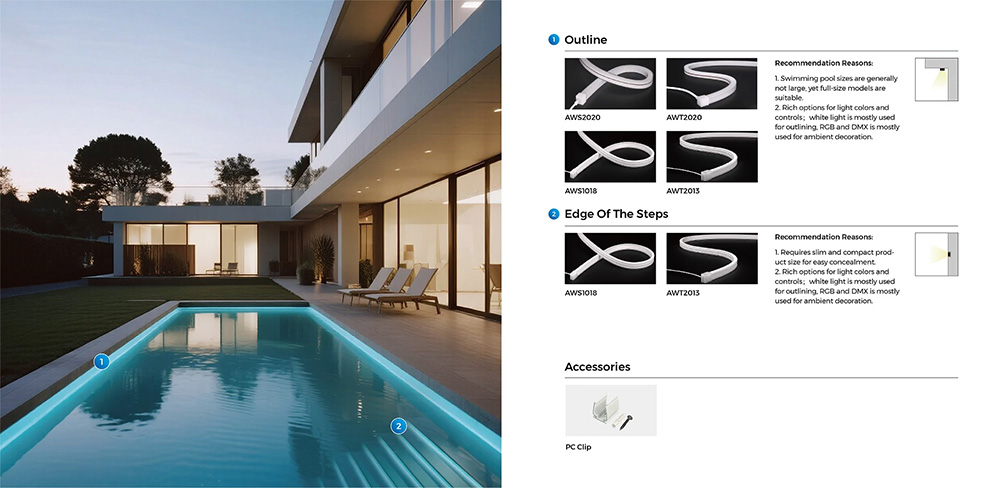

Unlike bulky underwater spotlights, LED strip lights can follow curves, corners, and irregular shapes. This allows designers to trace the outline of fountains, illuminate flowing water channels, create continuous light lines along pools, highlight stair edges in water landscapes, and add soft ambient lighting beneath the water surface. This flexibility enables lighting that feels like part of the water itself.

Unlike bulky underwater spotlights, LED strip lights can follow curves, corners, and irregular shapes. This allows designers to trace the outline of fountains, illuminate flowing water channels, create continuous light lines along pools, highlight stair edges in water landscapes, and add soft ambient lighting beneath the water surface. This flexibility enables lighting that feels like part of the water itself.

1.2 Smooth & Continuous Light Output

Underwater LED strips provide: no dark spots, uniform brightness, full diffusion in water, and continuous linear glow. This creates a modern, premium visual effect that traditional underwater lamps cannot replicate.

1.3 High Energy Efficiency

LED strips use significantly less power than old halogen underwater lamps while offering higher brightness, a longer lifespan, and lower maintenance needs. This is essential, especially in large outdoor fountains that run for many hours per day.

1.4 Safety in Wet Environments

Designed for submerged use, underwater LED strips operate at low voltage (12V/24V) to ensure safety, safe for swimmers, maintenance workers, and areas exposed to water spray.

1.5 Enhanced Aesthetics & Atmosphere

Underwater LED strips can create calm, elegant moods, dynamic and colorful scenes, vibrant RGB/RGBW animations, and dramatic highlights at night. This makes them ideal for hotels, plazas, malls, theme parks, lifestyle resorts, and luxury residences.

2. Key Applications of Underwater LED Strip Lights

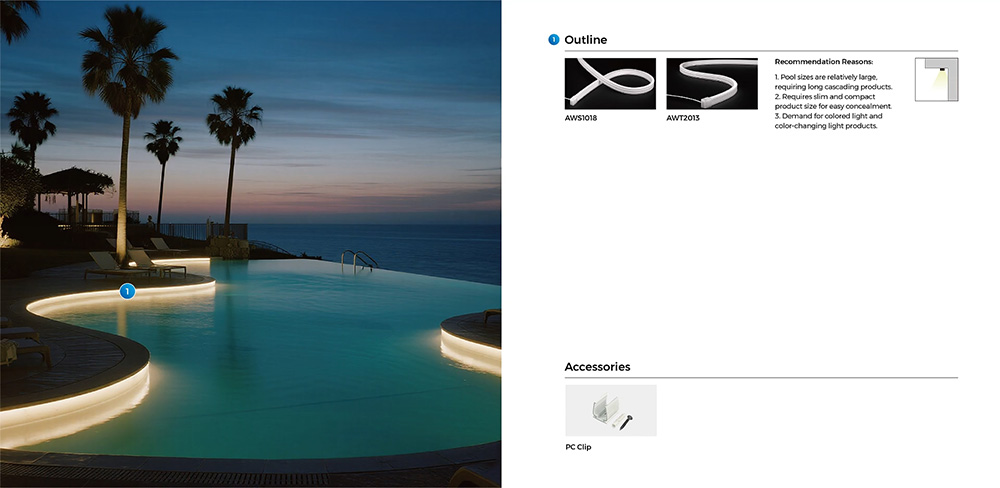

2.1 Public Fountains

Large outdoor fountains benefit from powerful brightness, wide diffusion, dynamic RGB lighting for shows, and seamless underwater lines.

Large outdoor fountains benefit from powerful brightness, wide diffusion, dynamic RGB lighting for shows, and seamless underwater lines.

LED strips can be placed around fountain basins, inside circular or ring fountains, along nozzle arrays, on steps and edges inside the fountain.

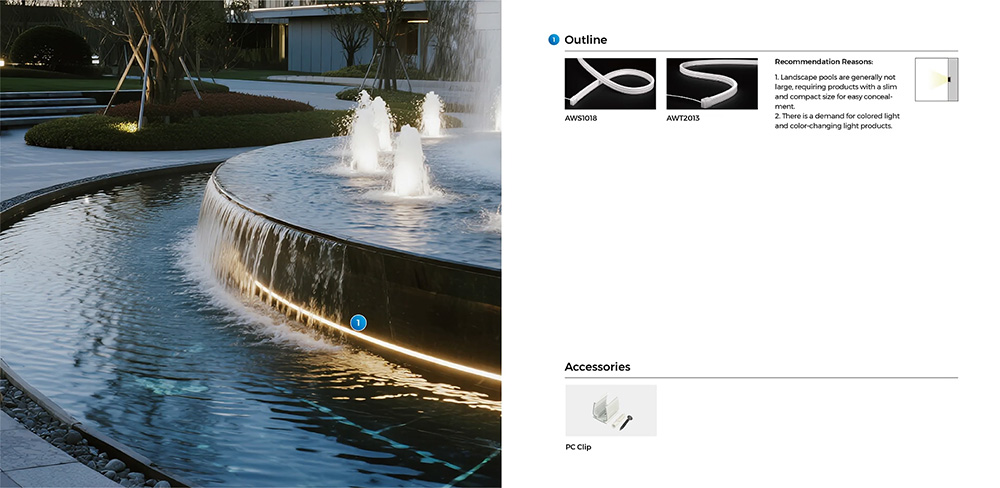

2.2 Waterfalls & Cascades

LED strips help emphasize the smooth flow of falling water, the textures of stone or metal behind waterfalls, the shimmering ripple effect, when installed behind water film or under the water outlet, they create elegant glowing curtains.

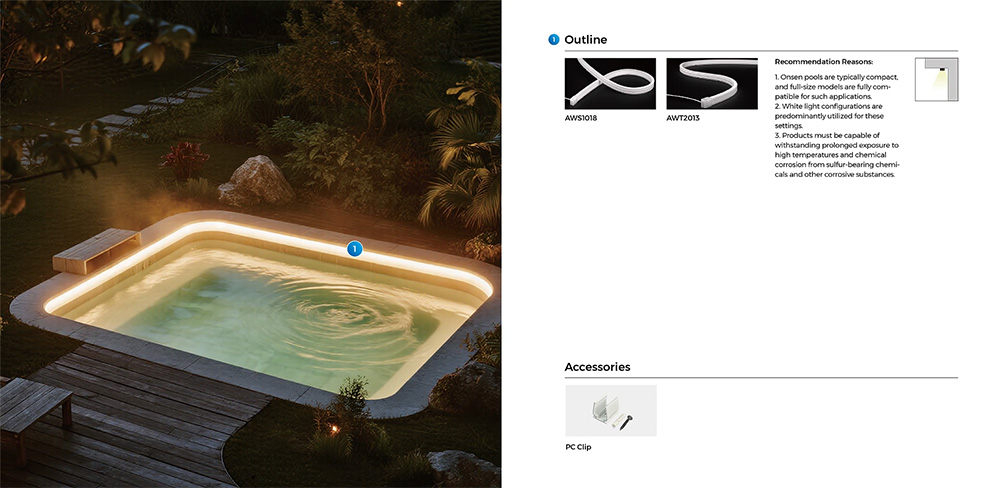

2.3 Swimming Pools & Spas

Applications include: Underwater perimeter lighting, steps, benches, and shallow zones, floating edges and infinity pools, and massage pool contours. He waterproof LED strips blend seamlessly into the pool design without bulky fixtures.

2.4 Ponds, Lakes & Garden Water Features

LED strips can highlight pathways around the water, aquatic plants, decorative stones, and sunken sculptures. RGB options allow seasonal themes or festival lighting.

2.5 Water Tunnels & Interactive Water Installations

Modern public art installations often use DMX RGB pixel strips, addressable LED effects, and Color-changing scenes. This creates immersive water-light experiences that attract visitors.

3. What Makes an LED Strip Suitable for Underwater Use?

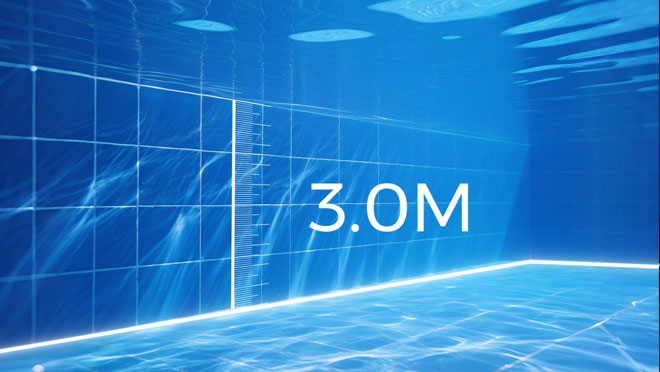

Not all LED strips are built for underwater applications. Standard IP65 or IP67 strips are not safe for long-term immersion. Underwater lighting requires IP68-level waterproofing at a minimum. Here are the essential standards:

3.1 True IP68 / IP69K Waterproof Protection

Underwater LED strips should have IP68 – fully submersible, IP69K – resistant to high-pressure water jets and extreme temperatures, and IK10 – strong impact resistance (for public fountains & vandal zones)

3.2 Advanced Encapsulation Materials

Top-tier underwater lighting uses silicone extrusion (preferred), which is excellent for waterproofing, UV-resistant, yellowing-resistant, chemical-resistant, and long lifespan; TPU (thermoplastic polyurethane), which is highly durable, highly transparent, and has strong environmental resistance. Inferior materials like epoxy often crack, yellow, or leak over time.

3.3 Marine-Grade Corrosion Resistance

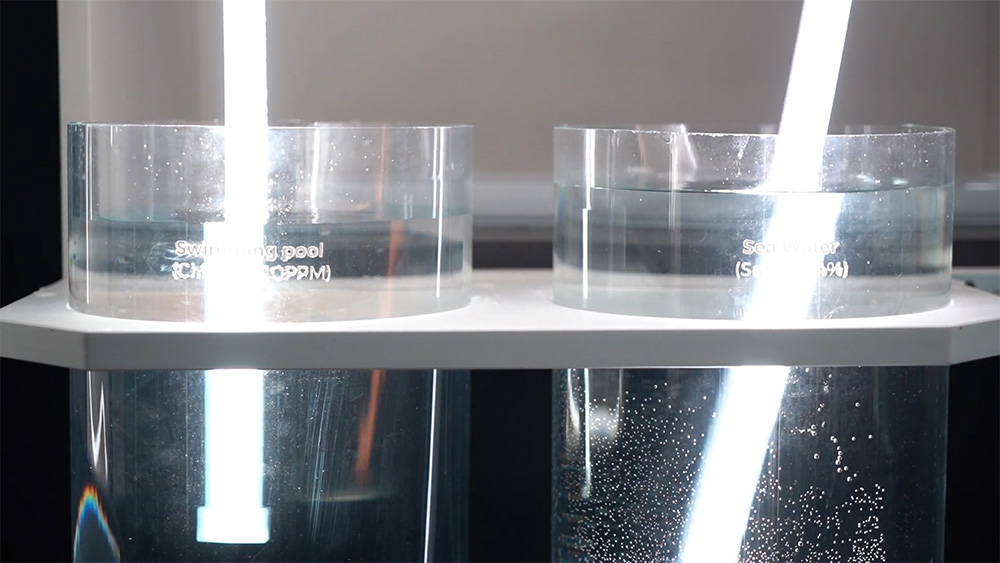

Water features may contain chlorine, salt water, alkaline substances, and minerals. LED strips should resist corrosion from saltwater pools, coastal installations, and hard water.

3.4 High-Quality LEDs & PCB

Key specifications include 2–4oz thick copper PCB, high-quality SMD LEDs (e.g., 2835, 5050, 2216), LM-80 certified LED chips, and Excellent thermal management. This ensures stable brightness under continuous 24/7 operation.

3.5 Safe Low-Voltage Operation

Underwater LED strips must operate at 12V or 24V DC. High-voltage (110V/220V) LED strips must never be used underwater.

3.6 Strong Adhesion & Mechanical Design

Underwater environments require anti-slip mounting channels, corrosion-resistant clips, screw-fastened joints, reinforced end caps, and adhesive tape alone is unsafe underwater.

4. Types of Underwater LED Strips

There are several types based on color, construction, and performance.

4.1 Single-Color Underwater LED Strips

Used for elegant architectural lighting.

Common colors: 2700K warm white, 3000K soft white, 4000K neutral white, 6500K cool white, amber, and blue (very popular in fountains).

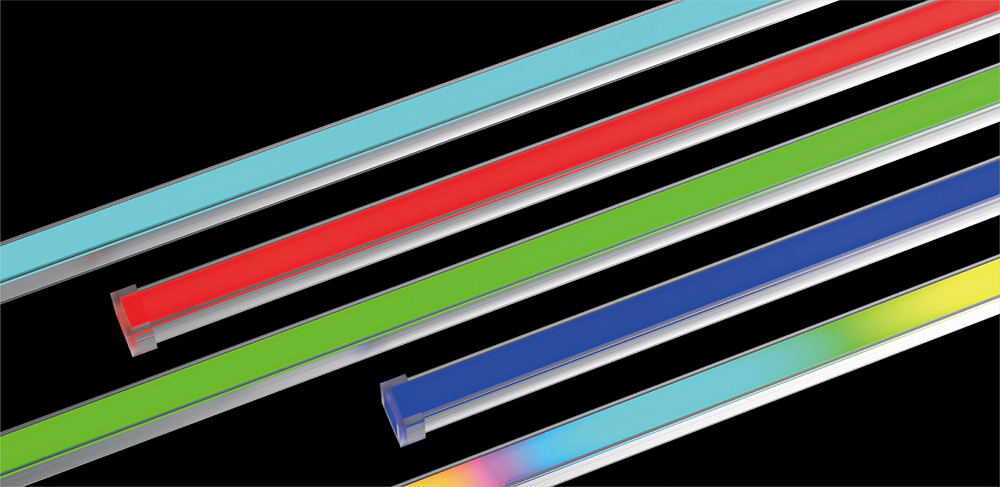

4.2 RGB Underwater LED Strips

Suitable for dynamic fountains, water shows, and themed lighting.

They provide: static colors, color-changing modes, fading, chasing, wave effects.

4.3 RGBW LED Strips

Combine RGB with a dedicated white chip: brighter white, warmer color tone, more natural scenes, ideal for premium hotels or landscapes.

4.4 SPI Pixel LED Strips (Individually Addressable)

Used in water shows and entertainment lighting.

Advantages: Fully programmable, Pixel-level animation, Light waves, meteor effects, rainbow transitions, widely used in: music fountains, water tunnels, theme parks.

4.5 High-Brightness Underwater LED Strips

Designed for large-scale fountains requiring strong illumination even through turbulent water.

5. Technical Requirements for Underwater LED Strip Lights

5.1 Brightness

Typical lumen ranges: standard underwater strips: 600–1200 lm/m, High-power underwater strips: 1500–2500 lm/m.

Typical lumen ranges: standard underwater strips: 600–1200 lm/m, High-power underwater strips: 1500–2500 lm/m.

5.2 Color Rendering Index (CRI)

For underwater environments: CRI ≥ 80 is acceptable, CRI ≥ 90 provides more vibrant colors.

5.3 LED Density

More LEDs per meter = smoother light.

Recommended: 60 LEDs/m – basic, 120 LEDs/m – premium, 180–240 LEDs/m – ultra-smooth.

5.4 Heat Dissipation

Even underwater, proper heat management matters. Thick copper PCB, high thermal conductivity silicone, high-efficiency LED chips, improve lifespan in long operating hours.

6. Waterproofing Technologies for Underwater LED Strips

There are several common waterproofing construction types:

6.1 Silicone Fully Extruded Integrated Body (Best)

Advantages: no internal air gaps, excellent durability, UV and chemical resistance, high transparency, long lifespan, ideal for long-term submersion, this is the leading technology in 2025.

6.2 Silicone + TPU Hybrid Structure

Used for heavy-duty applications: TPU exterior for toughness, Silicone interior for durability, highly resistant to impact & abrasion.

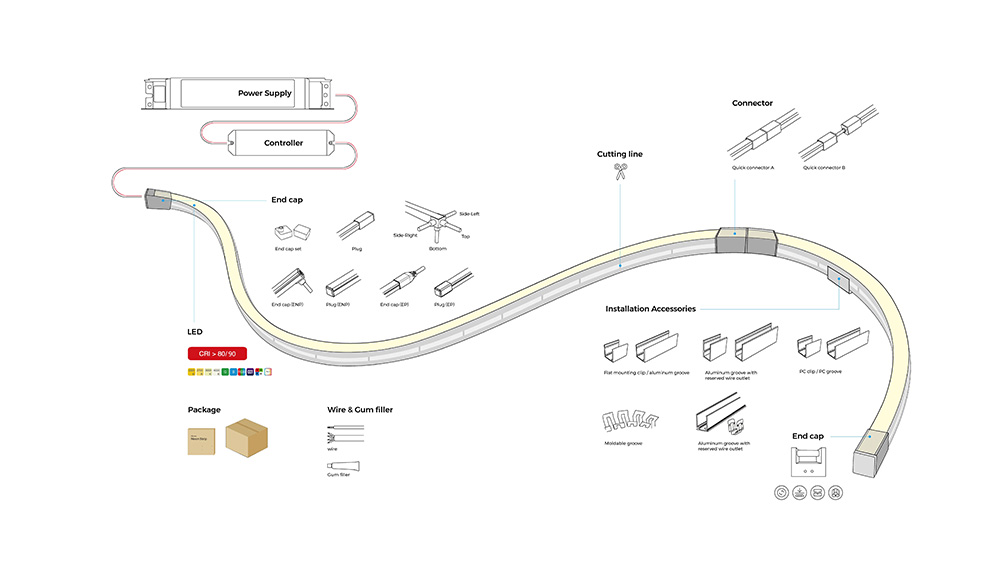

6.3 Injection - Molded End Caps

Critical for waterproof integrity. Features: Seamless joint sealing, prevents water ingress at wire entry, more reliable than glued caps.

6.4 High-Pressure Waterproof Connectors

IP68-rated connectors must be used: screw-tightened, double-sealed, anti-corrosion, and avoid cheap connectors that crack or leak.

7. Installation Methods for Underwater LED Strips

Proper installation determines long-term performance.

7.1 Mounting Channels

Use: Stainless steel clips, aluminum channels, polycarbonate waterproof channels, and anti-slip mechanical mounting. Do not rely on tape adhesives underwater.

7.2 Power Supplies

Requirements: Located outside the water, 12V/24V DC, Waterproof IP67/IP68 power supplies for outdoor zones, and surge protection.

7.3 Wiring Guidelines

Important rules: use underwater-rated cables, avoid cable joints underwater, ensure proper polarity, keep wiring inside conduits, and always use waterproof connectors

7.4 Avoiding Underwater Voltage Drop

Long underwater runs require: 24V instead of 12V, power injection every 5–10 meters, thick-gauge cables.

8. Common Problems & How to Avoid Them

8.1 Water Ingress

Causes: poor-quality encapsulation, weak end caps, and cheap connectors.

Solution: Use 100% silicone extruded strips; avoid low-cost epoxy-based strips.

Causes: poor-quality encapsulation, weak end caps, and cheap connectors.

Solution: Use 100% silicone extruded strips; avoid low-cost epoxy-based strips.

8.2 Yellowing or Dimming

Causes: UV exposure, chlorine corrosion, and substandard materials.

Solution: Use non-yellowing ocean-grade silicone.

8.3 Short Lifespan

Causes: overheating, Low-quality LED chips, Insufficient PCB copper

Solution: choose LM-80-certified LEDs, select 2–4oz copper PCBs

8.4 Flickering or Color Shift

Causes: poor soldering, voltage drop, moisture in connectors

Solution: regular power injections, reliable marine-grade connectors

9. How to Choose a Reliable Underwater LED Strip Manufacturer

Choosing the right manufacturer is crucial. Look for the following:

9.1 Full In-House Production Capabilities

A top manufacturer should have: LED chip encapsulation, SMT surface mounting, silicone/TPU extrusion, injection molding, and waterproofing production lines.

9.2 Strong R&D and Technical Team

This ensures: reliable product performance, continuous innovation, and support for custom projects.

9.3 Independent Product Testing

Look for testing abilities: waterproof and aging tests, thermal cycle tests, UV and salt spray tests, and electrical safety audits.

9.4 International Certifications

Underwater strips should have: CE, RoHS, REACH, UL / ETL, SAA, and LM-80 for LEDs.

9.5 Real Project References

Manufacturers with hotel projects, fountain installations, theme park water features, resort and pool projects are more trustworthy.

9.6 Long Warranty (At Least 5 Years)

Long warranties reflect confidence in product quality, better component selection, and better reliability.

9.7 Fast Support & Technical Service

Looking for on-site engineering support, DIALux/IES data, and installation guidance.

Conclusion

Underwater LED strip lights have transformed modern water feature design. Their slim profile, flexibility, strong waterproofing, and dynamic lighting capabilities make them ideal for fountains, pools, waterfalls, ponds, and public landscapes.

However, underwater environments are demanding high pressure, chlorine, corrosion, movement, and constant exposure. That's why selecting the right product and a reliable manufacturer is crucial.

When done correctly, underwater LED strips elevate water features into breathtaking visual art - combining function, safety, technology, and emotional atmosphere.

Underwater lighting is more than illumination - it's the art of turning water into light.