Blog

In-Depth Analysis of Outdoor Silicone Neon Flex Application Pain Points & ARCH NEON Series Solutions

In-Depth Analysis of Outdoor Silicone Neon Flex Application Pain Points & ARCH NEON Series Solutions

Ryan Lee.UpdatedJune 26, 2025|8 mins Read

Introduction

In building facade lighting projects, commonly used products such as LED strip lights, silicone neon flex, linear wall washers, and DMX-controlled dynamic chase fixtures, to create stunning visual effects. However, they often have significant problems during the actual application, which can compromise project cost, quality and service life.

The four main areas of concern are: 1. Weather Resistance Issues; 2. Long-term reliability concerns; 3. Optical performance defects; 4. Control system failures.

This article provides a detailed breakdown of these challenges, including their manifestations and root causes. It also offers potential solutions based on COLORS Lighting's ARCH NEON product core technologies.

1. Weather Resistance Issues – Inadequate Resilience to Harsh Environments

Outdoor products face extreme environmental exposure, demanding exceptional material stability.

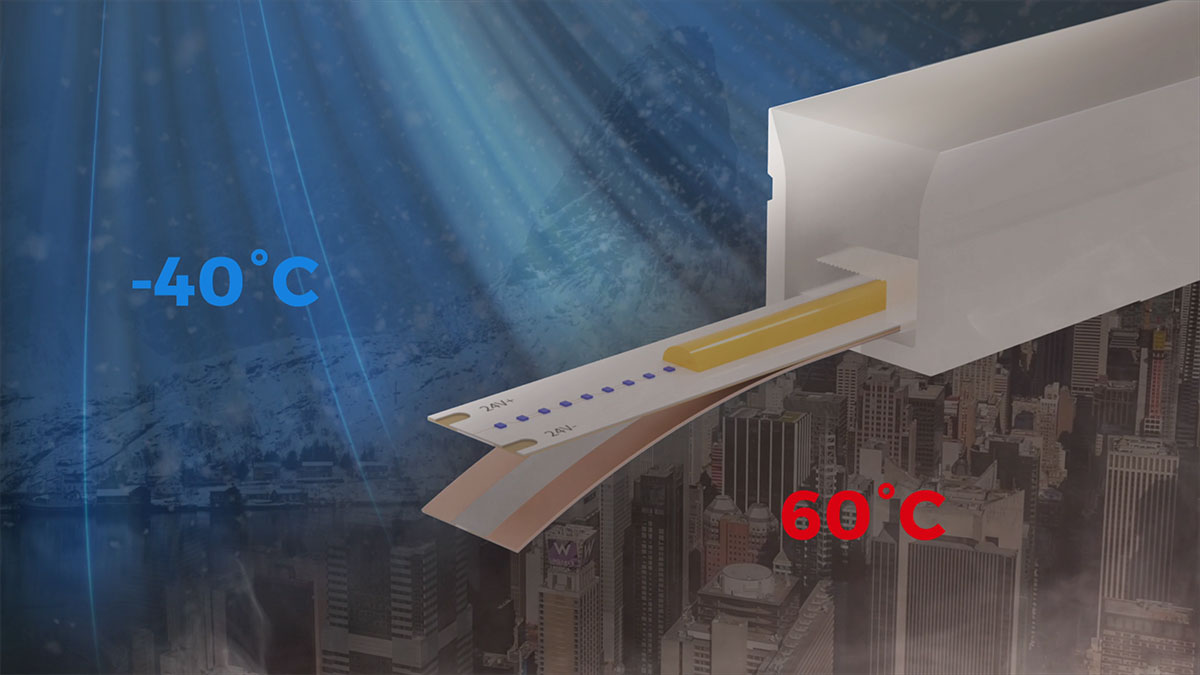

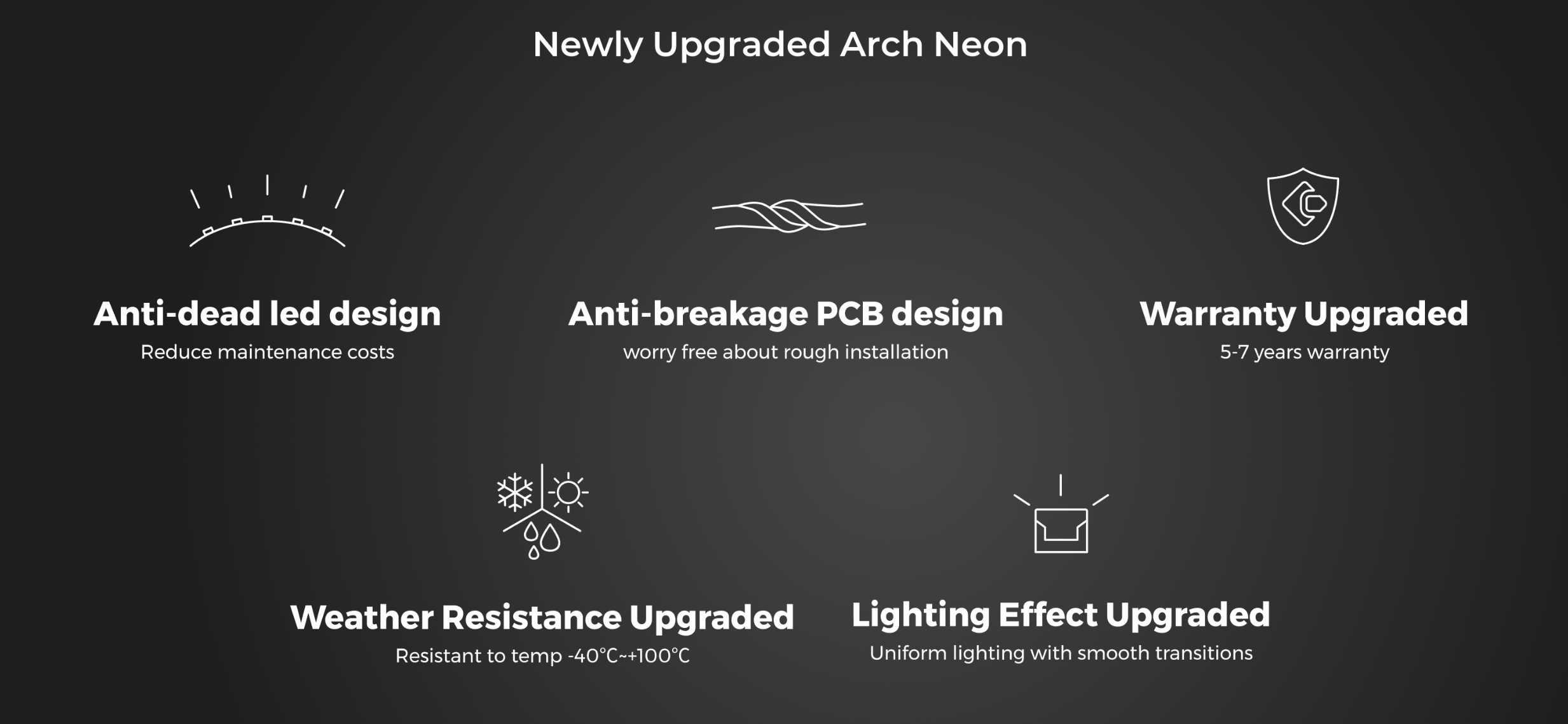

-1. Failure in Extreme Cold/Heat Conditions

- Manifestation:

Conventional products malfunction in extreme cold (<-20°C) or heat (>50°C). Electrolytic capacitors freeze below -40°C (DOC2), while components overheat and ignite at 80°C. Material thermal expansion/contraction mismatches cause structural fractures.

- Root Causes:

Brittleness of light sources, encapsulation materials, PCBs, or electronic components at low temperatures; thermal aging limits exceeded in high temperatures.

- Solution:

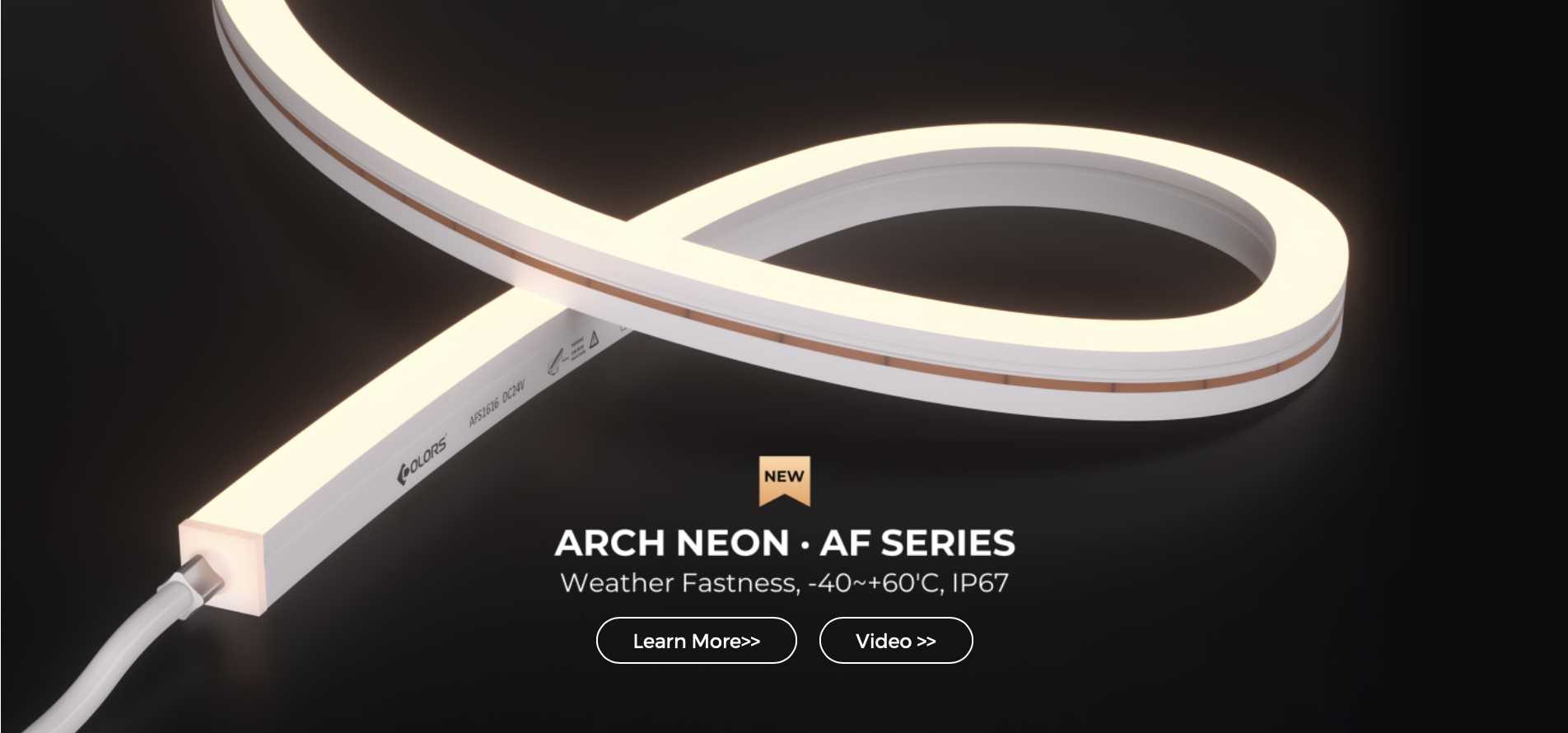

Deployment of flip-chip technology (e.g., AF Series Neon Strips) with an extended operating range of -40°C to +60°C, combined with extreme-temperature-resistant silicone and electronic components.

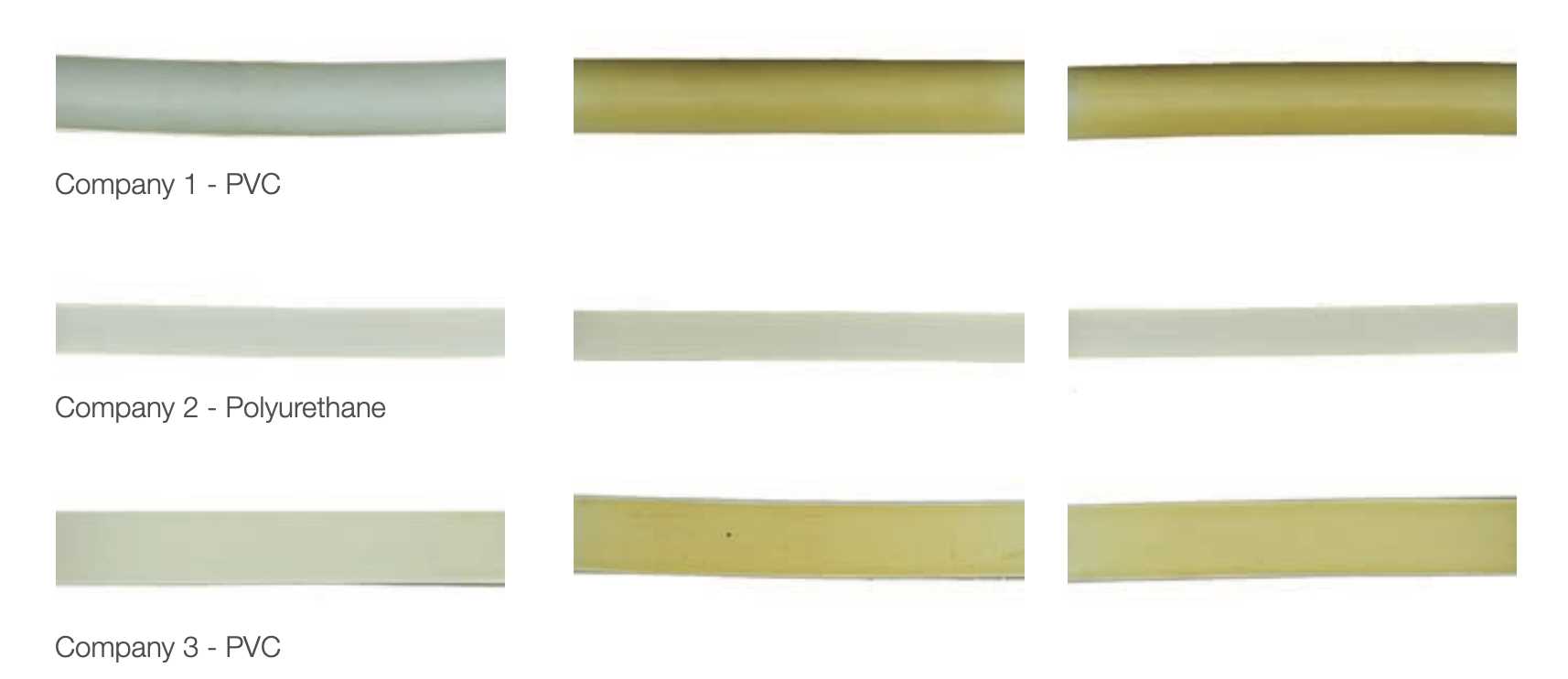

-2. Yellowing After Prolonged Outdoor Exposure

- Manifestation:

Surface encapsulation yellows or clouds due to UV/ozone/heat exposure, reducing transmittance and causing chromatic shifts (warm/cool bias), degrading optical performance and aesthetics.

- Root Causes:

Poor UV resistance of conventional PVC; insufficient anti-UV additives in silicone formulations.

- Solution:

Meteorological-grade silicone co-extrusion with 3% UV-blocking nanoparticles, validated by 3,000-hour UV testing (equivalent to 9 years outdoors), maintaining ∆E<1.5 color shift.

-3. Cracking During Long-Term Use

- Manifestation:

Joints, corners, or stress concentration zones crack under thermal cycling, compromising waterproofing and causing internal failures.

- Root Causes:

Low elasticity/tear resistance of standard silicones; structural stress at seams; embrittlement in cold.

- Solution:

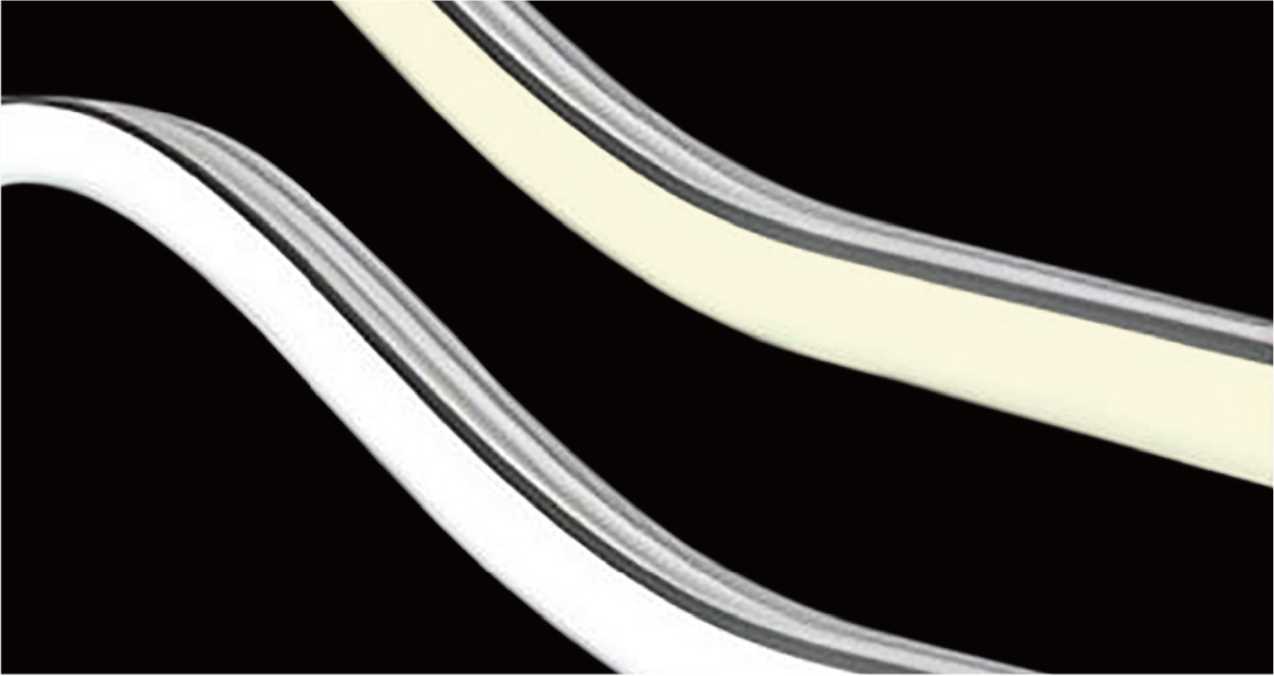

Triple-layer silicone extrusion and patented T-slot structural design to distribute stress and prevent seam cracking.

4. Cable/Joint Water Ingress

- Manifestation:

Low IP ratings or flawed waterproof structures allow moisture penetration, causing short circuits, dead pixels, and corrosion. Capillary action (wicking) exacerbates infiltration.

- Root Causes:

Inadequate sealing (e.g., adhesive-only joints); substandard IP ratings (e.g., IP44/IP54 vs. required IP65+).

- Solution:

IP67-rated integrally molded plugs + dual waterproofing (internal structure + anti-siphon terminals) (EXCEL1).

2. Long-term Reliability Concerns – Stability Deficits During Installation/Operation

Physical robustness and electrical reliability directly impact longevity and maintenance.

-1. Dead Pixels During Installation/Use

- Manifestation:

Individual LEDs fail during handling, installation, or operation, creating dark spots.

- Root Causes:

Fragile wire bonding in conventional LEDs, mechanical stress during installation.

- Solution:

Flip-chip technology (AF Series Neon Strips) with gold-free interconnects, validated by 720° torsion testing for 5,000 cycles.

-2. Entire Segment Failure from Single Dead Pixel

- Manifestation:

Single LED failure cascades to an entire cut segment (≥3 LEDs), creating conspicuous dark zones.

- Root Causes:

Series circuit design.

- Solution:

Multi-core parallel circuitry – dead pixels affect only themselves, achieving "imperceptible flaws at distance".

-3. PCB Fracture ("Broken Board") Leading to Extended Blackout

- Manifestation:

Physical PCB breakage causes extended unlit sections (>1 cut segment), requiring complex repairs.

- Root Causes:

Thin/rigid PCBs; improper bending during installation.

- Solution:

Backplane dual-power redundancy – backup circuits maintain operation post-fracture.

-4. Cable Pull-out at Connectors

- Manifestation:

Tension on cables dislodges internal connections, causing partial/total failure.

- Root Causes:

Inadequate strain relief; substandard terminations.

- Solution:

Strain-relief plugs tested to 650N pull force (~66kgf), protecting internal PCBs (EXCEL1).

3. Optical Performance Defects – Visual Quality & Energy Efficiency Challenges

Optical output quality and energy efficiency are critical for project success.

-1. Batch-to-Batch Color Inconsistency

- Manifestation:

Visible color temperature shifts (±200K) or brightness mismatches between batches disrupt uniformity.

- Root Causes:

Phosphor formulation variances; silicone batch differences.

- Solution:

ANSI-standard color bins + 5-step McAdam ellipse control for seamless integration.

-2. Non-Uniform Illumination (Edge-to-Center Variation)

- Manifestation:

Uneven brightness ("hot spots" or dark edges) due to poor optical design.

- Root Causes:

Discrete LED emissions; inefficient light-guiding structures.

- Solution:

High-transmittance extrusion design + micro-optical diffusers for >90% uniformity.

-3. Unsmooth Dynamic Color Transitions

- Manifestation:

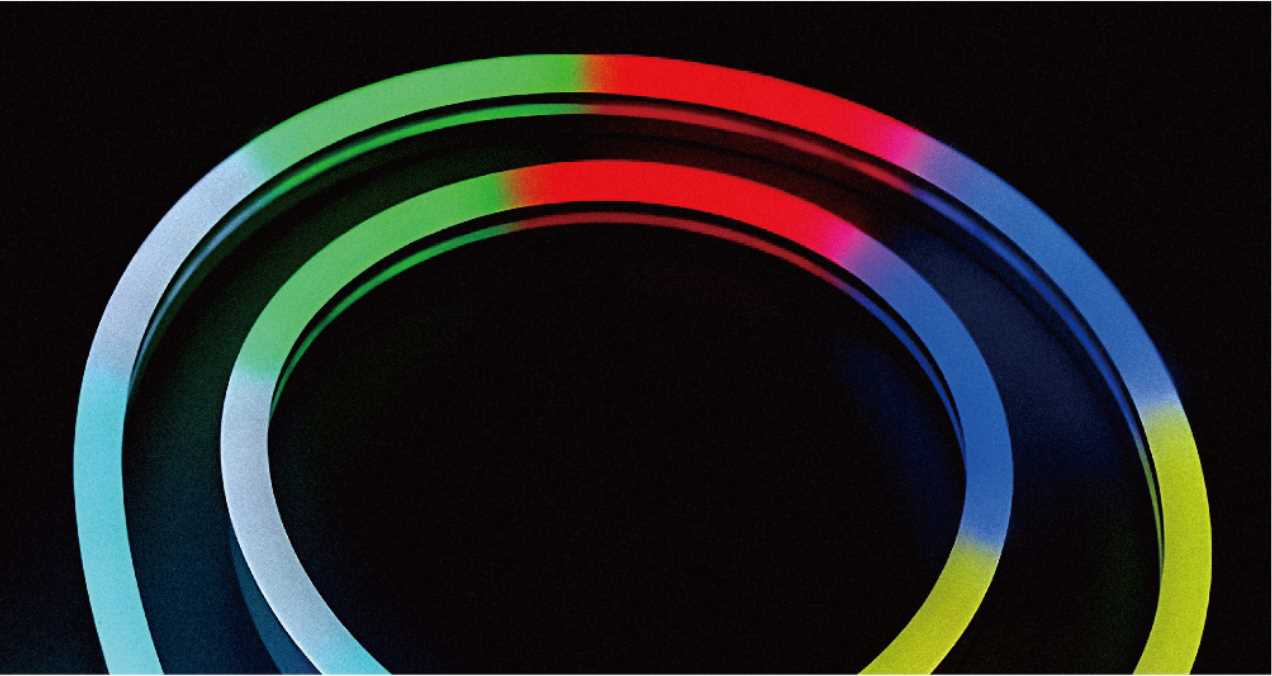

Choppy gradients, color banding, or desynchronization in RGBIC applications.

- Root Causes:

Low-bit-depth ICs, protocol incompatibility, and signal interference.

- Solution:

16-bit processing ICs (65,536 grayscale levels) + compatibility with Art-Net, sACN, PixLite.

-4. Low Luminous Efficacy & High Power Consumption

- Manifestation:

Excess power draw to achieve target brightness increases operational costs.

- Root Causes:

Poor LED efficiency; optical/thermal losses.

- Solution:

High-efficiency optical structure delivering 40% energy savings at equivalent brightness.

4. Control System Failures – Compatibility & Signal Integrity Challenges

Complex control systems face integration and signal robustness hurdles.

-1. Compatibility Issues

- Manifestation:

Protocol mismatches (e.g., DALI vs. DMX512) cause erratic behaviour with third-party controllers/sensors.

- Root Causes:

Narrow IC protocol support; non-standard implementations.

- Solution:

Industry-standard protocol compliance (e.g., ANSI E1.11, IEC 62386).

-2. Signal Interference & Long-Distance Degradation

- Manifestation:

Flickering, signal dropouts, or data corruption near EMI sources (e.g., motors) or over long cables.

- Root Causes:

Unshielded cables, poor EMC design, and a lack of signal repeaters.

- Solution:

EMC-optimized circuits + shielded twisted pair (STP) cables; signal boosters/isolators or fiber optics for >100m runs.

Conclusion

By dissecting these four pain points and leveraging advanced technologies – flip-chip LEDs, weather-resistant silicones, redundant power systems, and interference-immune controls – project stakeholders can:

- Identify Risks Early: Anticipate failures during design/specification.

- Optimize Product Selection: Prioritize solutions with validated performance data.

- Enhance Implementation: Focus on critical processes (waterproofing, signal routing, EMI mitigation).

- Ensure Long-Term Performance: Achieve reliable, high-quality, energy-efficient lighting with minimal maintenance.

This technical analysis provides a rigorous foundation for successful architectural lighting projects.

COLORS LIGHTING delivers these innovations through its ARCH NEON series silicone neon strips, serving global outdoor lighting needs with high-performance solutions.

COLORS Lighting, the LED linear lighting solutions provider, specialises in the research, development, and manufacturing of high-quality lighting products, which have been certified by all major national markets and are exported to more than 100 countries and regions worldwide.

Our product portfolio covers Neon Strips, LED Strips, Infinite Lights, Linear Lights, Track lights, and Downlights. COLORS Lighting provides integrated and professional lighting solutions for residential, hotel, office, commercial, and outdoor spaces.

We have a professional lighting design team, key projects to provide pre-design planning, mid-term selection simulation, post-installation and commissioning of professional support. For key projects, we can cooperate with designers and engineers to deepen the pre-sale product application program. Welcome to contact us and tell us which products you prefer, or let us know what type of lighting solution you need. Let us help your lighting project! COLORS Lighting, Colorful Life!