Manufacture

Independent Production Throughout the Entire Supply Chain

COLORS Lighting operates a complete, high-quality production line covering SMD Encapsulation, SMT Surface Mounting, Neon Extrusion, Hardware Spraying, and Finished Product Assembly.

01

SMD

Encapsulation

Encapsulation

- Core Component of

LED Strips & Neon Strips - Gold Wire Inside

- Enhanced Bracket

02

COF

Production Line

Production Line

- 2 Lines of COF Strip

Production

03

Light Source

SWT Workshop

SWT Workshop

- Solder Paste Printing

- SMT Placement

- Reflow Soldering

04

Silicone

Extrusion Workshop

Extrusion Workshop

- 5 Extrusion Production Lines

- Cutting Point Visible

Extrusion Tech - Anti-static Surface

Processing Tech

05

PC Mask

Extrusion Workshop

Extrusion Workshop

- Compounding

- Extrusion

- Precision Cutting

06

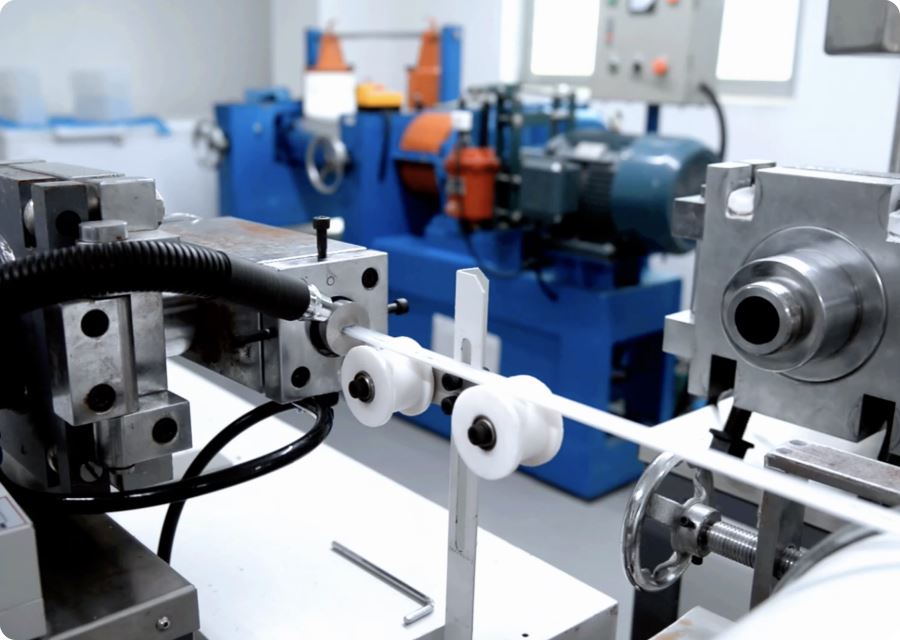

Aluminum Profile

Machining Workshop

Machining Workshop

- Pol Bending

- Cutting

- Milling & Drilling

07

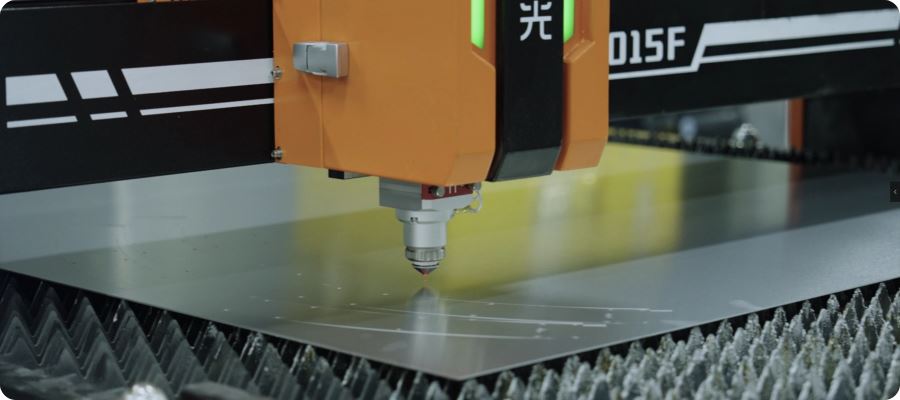

CNC Machining

Workshop

Workshop

- Laser Cutting

- CNC Welding

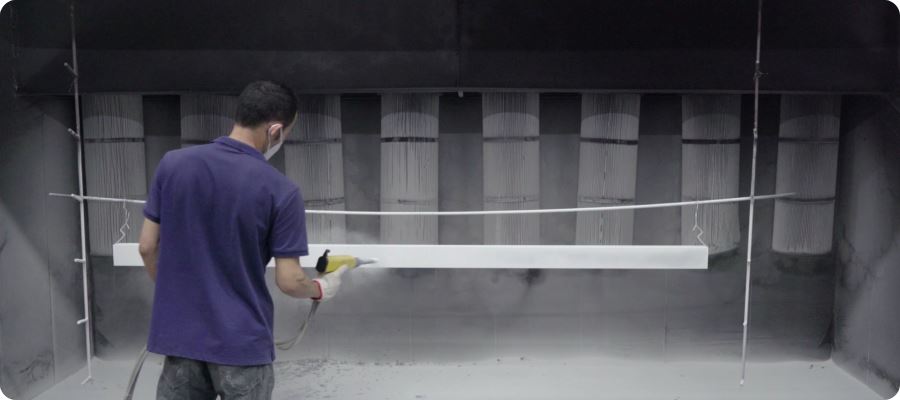

08

Flexible Customized

Spraying Workshop

Spraying Workshop

- Polish

- Spray Painting

- Baking

09

Product Assembly

Workshop

Workshop

- Products Assembly

- Aging Test

- Final Product Inspection

10

Automatic

Packaging Line

Packaging Line

- Blister Packaging

- Carton Sealing

- Stretch Wrapping

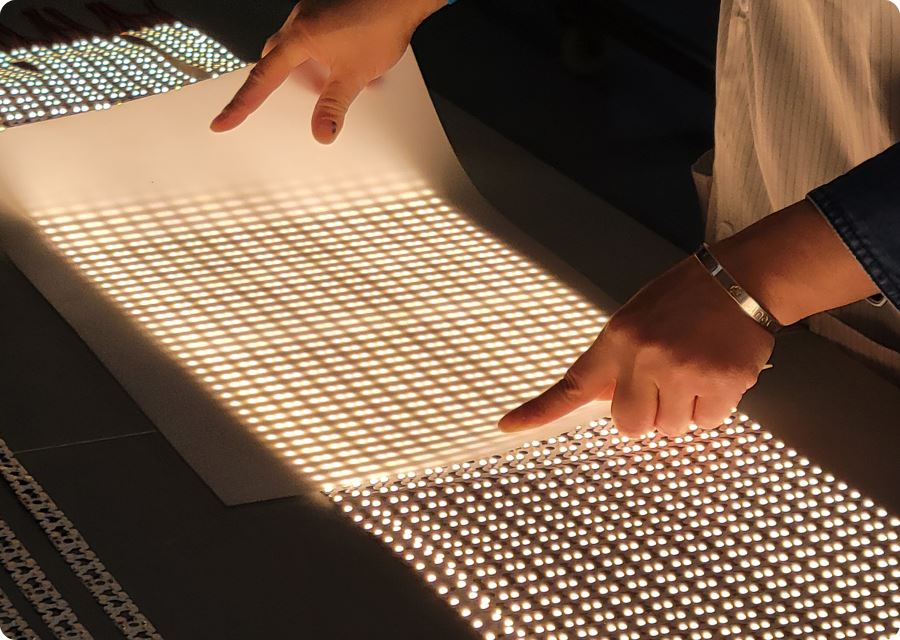

SMD

ENCAPSULATION

- Core Component of LED Strips and Neon Strips

- Gold Wire Inside

- Enhanced Bracket

- Strict Binning Management

- Customization Support

- Dedicated Only for Self Use

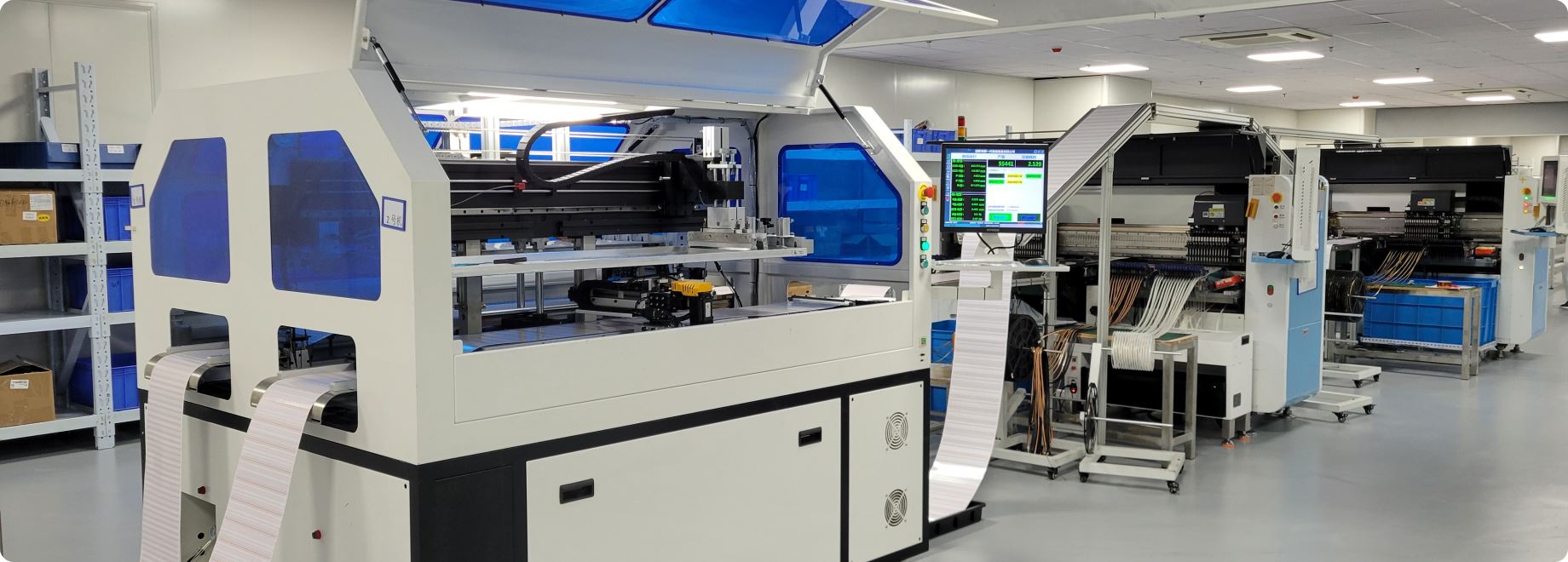

SMT

SURFACE MOUNTING

- Highly Automated Production

- Precisely Match Resistance Based on the LED's VF to Effectively Control Product Power Consumption

- 100% QC at Every Step of the Production Process

- Capacity up to 40,000m Per Day

R2R & COF

PRODUCTION LINE

- Highly Automatic Production with R2R Tech

- 2 Lines of COF Strip Production

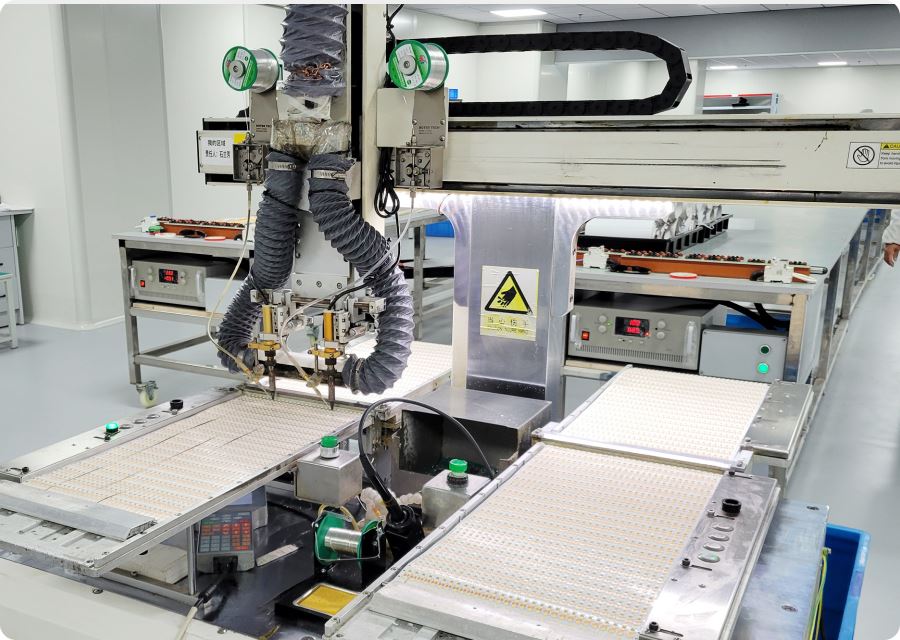

LED STRIP

PRODUCTION LINE

- Auto-soldering & Manual Soldering

- Onsite Support Quickly Solves Quality Issues

- QC Inspection at Every Step of the Production Process

- Capacity up to 40,000m Per Day

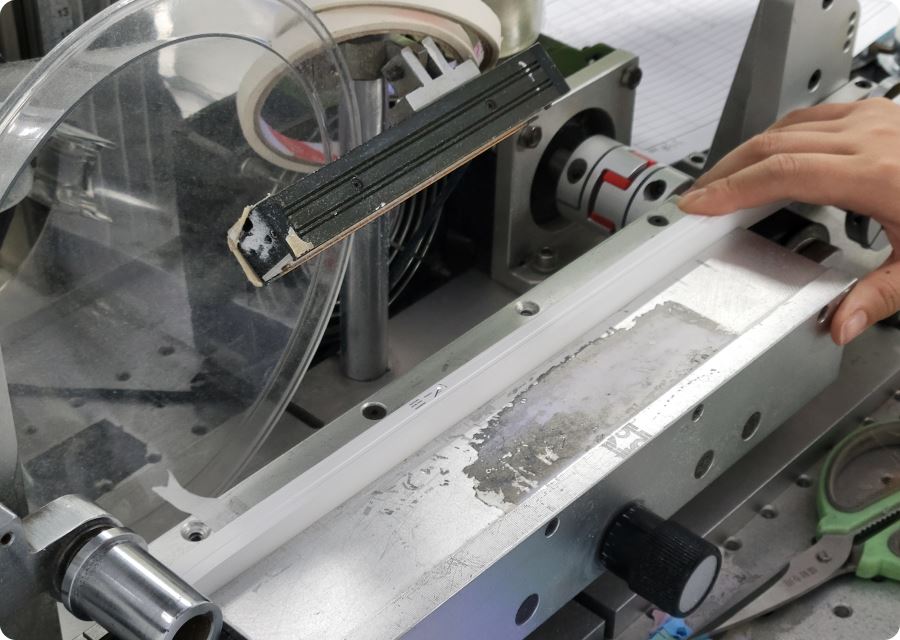

NEON STRIP

PRODUCTION LINE

- 5 Extrusion Production Lines

- Cutting Point Visible Extrusion Tech

- Anti-static Surface Processing Tech

- Capacity up to 14,000m Per Day

LUMINAIRE

MANUFACTURING

- Aluminum Machining Workshop

- CNC Finishing Workshop

- Customized Spraying Workshop

- PC Cover Extrusion Workshop

- Luminaires Assembly Workshop

- Automatic Packaging Line

WAREHOUSING

PIPING

- Forklift Operation in Warehouses

- WMS System Storage Management

- Customers Determine Logistics Information

- Delivery to Global Customers through Logistics Companies

Quality Assurance

COLORS Lighting implements comprehensive quality control across five key stages: Pre-production R&D, Incoming Material Inspection, In-process Production Control, Finished Product Inspection, and After-sales Service.

100% First Piece Approval

Strict R&D standards are enforced, with on-site Incoming Quality Control (IQC) inspections, and trial production is conducted before mass production.

Reliability Testing in R&D

Raw Material Testing

First Piece Quality Inspection

In-process Sampling Inspection & Pre-shipment Final Inspection

All products undergo sampling inspections, scheduled patrol inspections every two hours, and a final inspection before shipment.

Random Sample Inspection

Regular Inspections

Final Inspection

Quality Certification System

lSO9001 Quality System and lSO14001 Environmental System Certifications for Both Production Bases.

All products have passed tests of third-party authoritative laboratory institutions and have obtained multiple quality certifications.

All products have passed tests of third-party authoritative laboratory institutions and have obtained multiple quality certifications.

More About Us