Blog

Can You Cut LED Strip Light Anywhere? Why Our Modular Design Solves The Problem

Can You Cut LED Strip Light Anywhere? Why Our Modular Design Solves The Problem

Joyce Alva.UpdatedMay 28, 2025|9 mins Read

Introduction

Whether for architectural facades, commercial installations, or accent lighting in residences, LED strip lights have emerged as the preferred option for modern lighting projects. They are perfect for a variety of applications due to their elegant design, energy economy, and adaptability. However, one of the most common queries we get is:

Is it possible to cut LED strip lights to the precise length I need?

The answer is not quite really and it is not as straightforward as some would hope. To be honest, while LED strips are designed to be cut, doing so improperly and incorrectly can lead to serious performance issues, failures, or even safety hazards to some extent.

In this article, we will share something you need to know about cutting LED strip lights and clarify why normally LED strips can not be cut just anywhere, what risks are involved, and most importantly, how our modular LED strip design solves the problem, giving you full control over your LED strips with free cutting.

What is LED strip?

An LED strip, tape, or ribbon light is a flexible circuit board populated by surface-mount light-emitting diodes (SMD LEDs) and other components that usually comes with an adhesive backing. Traditionally, strip lights had been used solely in accent lighting, backlighting, task lighting, and decorative lighting applications, such as cove lighting. But nowadays, they are widely used in residential, commercial, and architectural lighting due to their versatility, energy efficiency, and ease of installation.

Key features of LED strip

Flexibility

The flexibility is one of the most valuable features of LED strip lights. LED strips are designed to bend and conform to different shapes, making them available for a variety of curved or irregular surfaces. This characteristic makes them ideal for creative and bespoke lighting installations where rigid lighting solutions would not be suitable. The flexibility is achieved by the design of the FPCB and the use of small, surface-mounted LEDs.

A Flexible Printed Circuit Board(FPCB) is a type of circuit board constructed on a flexible substrate, which differs from the traditional rigid PCBs. FPCB makes the circuit to be bent, making it capable of applications where space is limited or where the circuit needs to conform to a specific shape. Flexibility, durability, space saving, thermal resistance, and chemical resistance are all the key advantages of FPCB.

Adhesive Backing

The majority of LED strips come with a 3M adhesive backing, which allows for easy and quick installation on a variety of surfaces. Normally, this backing is a double-sided tape made by 3M or other adhesive manufacturers. Both the ease with which the LED strip sticks to a surface and the time it stays in place can be considerably influenced by the quality and kind of adhesive used.

Cuttable

Most LED strips are designed with specific cutting points, usually marked with a scissor icon or a dotted line, making it easy to adjust the length to fit the application, providing customization for specific length requirements. The ability to cut LED strip lights at designated points is a key feature that allows for customization and flexibility in various lighting projects.

Low Voltage

The majority of LED strips are made with precise cutting points, often indicated by a dotted line or a scissor symbol. This allows for easy length adjustment to suit the application and allows for customisation for certain length needs. Customization and versatility in a variety of lighting projects are made possible by the ability to trim LED strip lights at certain spots.

Variety of Colors

LED strip lights come in a wide range of colors, including single-colour RGB (Red, Green, Blue), and RGBlC(Red, Green, Blue, Individual Control) options, offering extensive options for creating different ambiances and effects. The color variety is achieved through different types of LEDs and control systems, allowing for everything from static single colors to dynamic, multi-colored displays.

Why can't all LED strip lights be cut anywhere?

Not all LED strip lights can be cut anywhere because of the way they are designed and how their circuits are arranged. Most standard LED strips have designated cutting points that are specifically designed to allow the strip to be shortened without damaging the entire circuit.

Here are the reasons why LED strips have designated cutting points:

Circuit Design

LED strips consist of multiple individual circuits connected in series or parallel, each containing a series of LEDs and a resistor, connected in a repeating pattern, connected in a repeating pattern. The circuit design of LED strip lights is a fundamental element that dictates where the strips can be safely and easily cut. These circuits are designed to operate at a specific voltage; cutting the strip at any point other than the designated point can break these circuits and cause sections of the strip to fail.

Cutting Point Markers

Cutting point markers are visual indicators on LED strip lights that show you where it is safe to cut the strip without damaging the circuitry. Designated cutting points are usually marked with a scissors icon or a dotted line. These markers are essential for customizing the length of LED strips for various applications while ensuring they continue to function correctly.

Copper Pads

Cutting points are often located between copper pads, which are used to connect the strip to a power source or to reconnect cut sections. Copper pads are small, exposed areas of copper on the surface of an LED strip, typically found at the designated cutting points. They serve as electrical contact points, allowing you to reconnect the strip to a power source or join two cut sections together. Cutting at these points ensures that you can still solder or use connectors to re-establish the circuit.

While most traditional LED strip lights offer some degree of cuttability, the fixed cutting points and circuit limitations often fall short in real applications, especially in projects requiring precise lengths, seamless curves, or fully customized layouts. These limitations can complicate installations, reduce design flexibility, and even lead to performance issues when improperly cut. That is why we have developed a new generation of LED strip lights that truly enable free-cutting, giving you the ability to cut “anywhere along the strip” without compromising safety, performance, or reliability. In the next section, we will explore how our Free Cutting Series design works and why it is a game-changer for architects, designers, and lighting professionals.

Introduction of COLORS Lighting Free Cutting Series

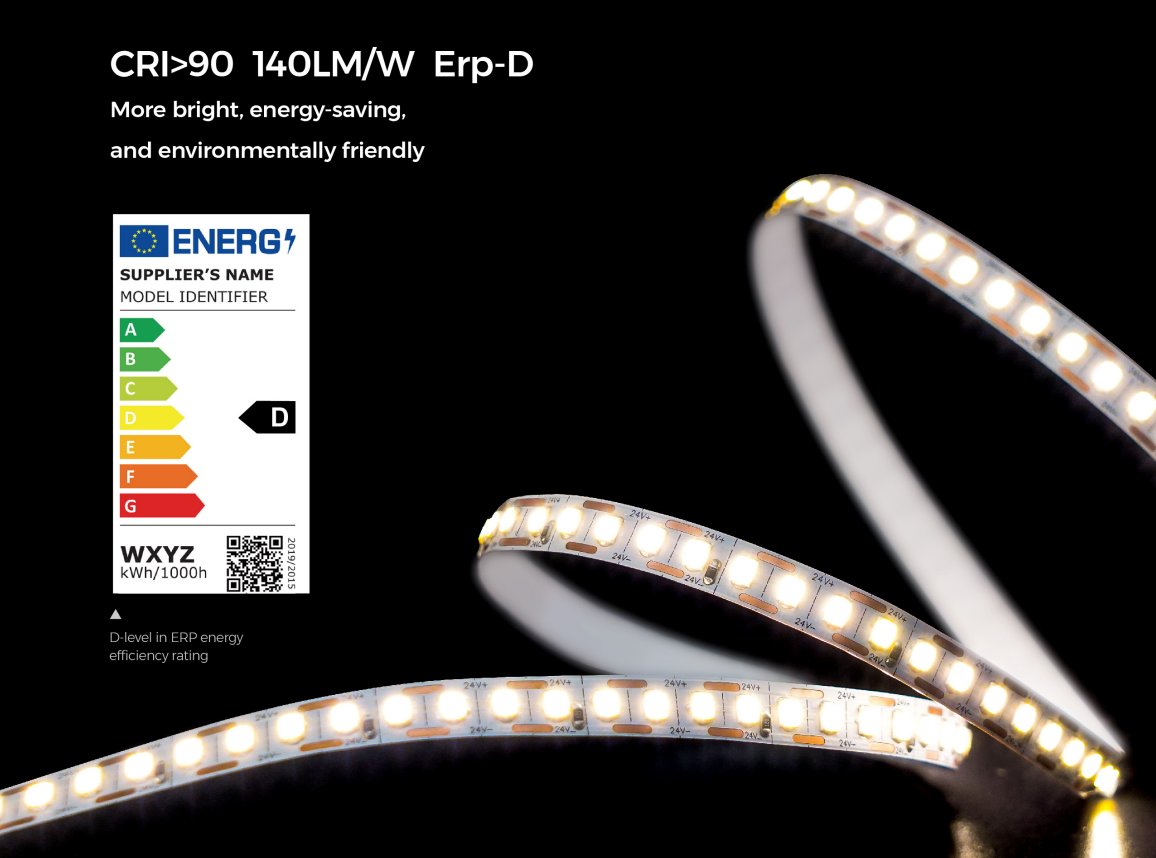

Free Cutting Series LED strip lights are a 2-in-1 product that allows for a reduction of stock by 50%. The integrated LED strips with high efficiency and free-cutting capability are included. These strips feature customized 24V LEDs that offer a CRI of 90 and outputs up to 140 lumens/watt. The 5mm, 10mm, and 8mm strips are also easily connected with solder-free connectors. Also included are solder-free profiles that make it easy to light cabinets.

Innovative features of the Free Cutting Series LED strips

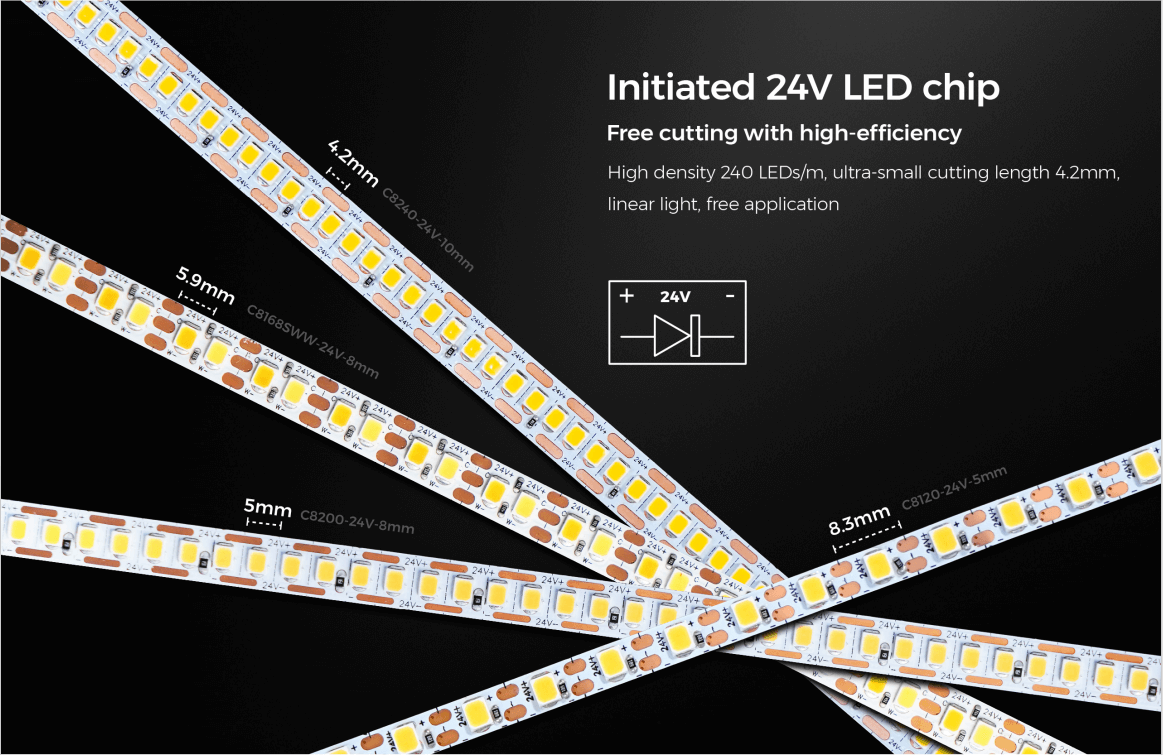

Customized 24V Chips

COLORS Lighting is the first company to package the large 24V chips into SMD2835 SMD LEDs, specifically for linear lighting applications. Our Free Cutting Series LED strip lights are therefore both high-efficiency and free-cutting, solving the problem with LED strips that only use 18V chips. Most LED strip lights on the current market use 12V or 18V chips. These chips often limit brightness, efficiency and circuit design.

COLORS Lighting has successfully overcome the problem of standard LED strips' limited voltage handling by pushing the limits with custom 24V chips. The Free Cutting Series allows for random cutting, but also offers high luminous efficiency and low current draw. This results in better energy management, improved thermal management and reduced voltage drops across longer runs. This innovation allows for bright, uniform, and stable lighting, even in large or demanding installations.

The integration of high-voltage chip technology into the compact, proven SMD2835 format ensures compatibility with existing manufacturing and accessory processes. This makes it easier for designers and installers to upgrade projects without compromising quality or efficiency. This innovation reflects our commitment to providing innovative solutions that are in line with the changing needs of modern lighting.

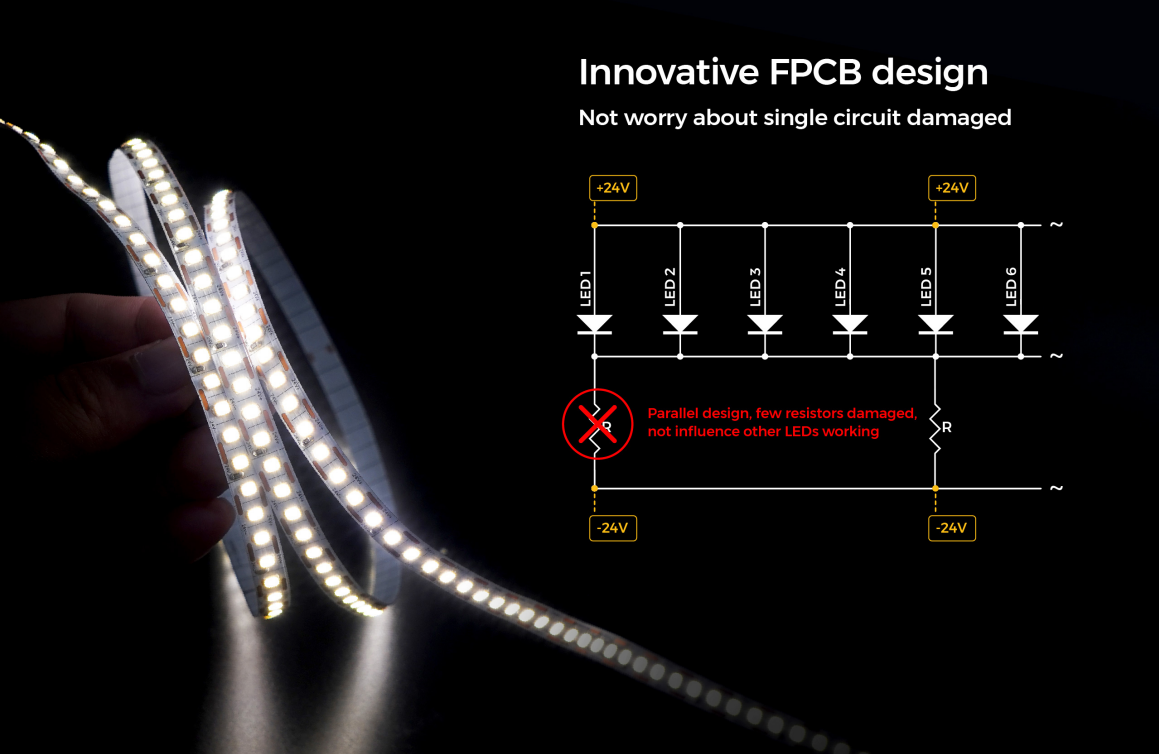

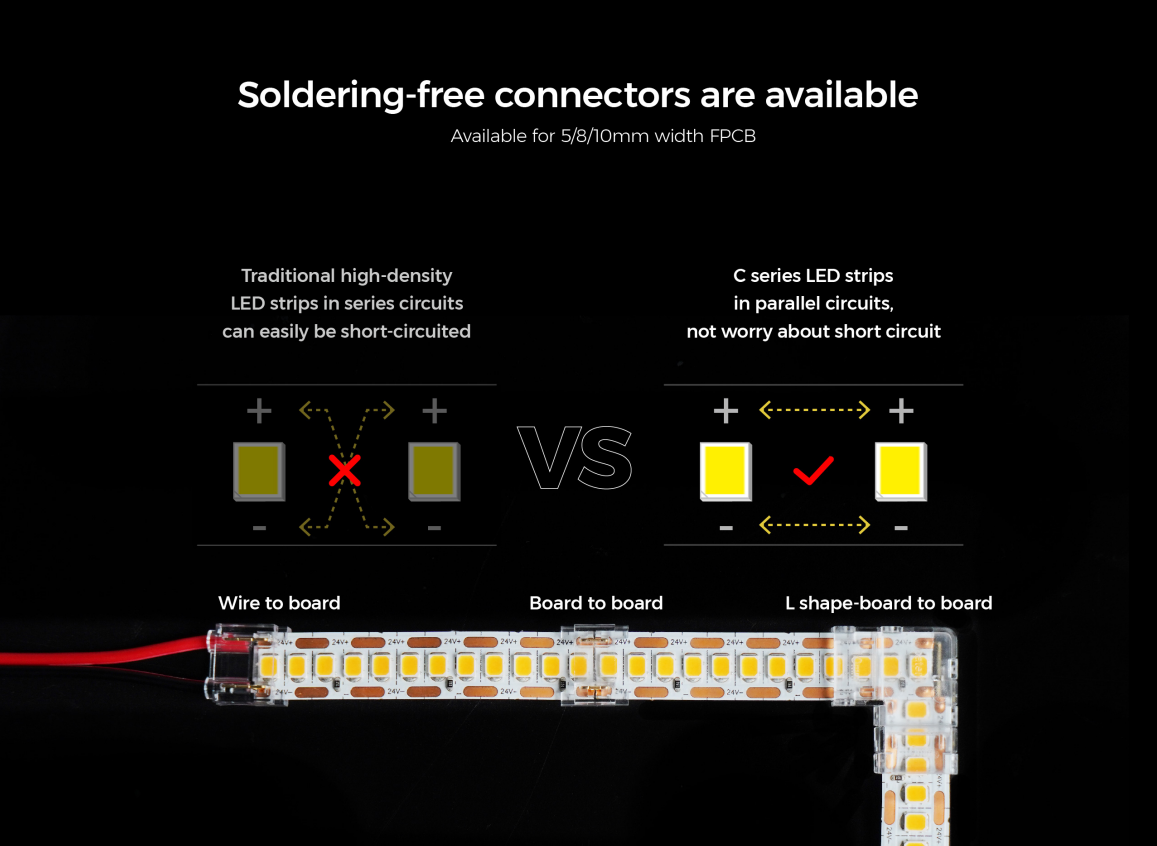

FPCB Parallel Design

Our engineers have innovatively designed the FPCB, LEDs in parallel, rather than the traditional series circuit layout. In a parallel design, each LED or group of LEDs operates as an independent circuit. This means that if one LED or a segment fails or is damaged, the rest of the strip will continue to function normally, without affecting the performance of the entire system. This design also makes it possible to use soldering-free connectors for both low and high-density LED strips.

This structure dramatically enhances the reliability and lifespan of the strip, especially in demanding applications or environments where mechanical stress or improper handling may occur. Additionally, because the parallel design minimizes the number of components, particularly resistors that are commonly damaged in series circuits, it reduces the risk of failure and simplifies maintenance.

What's more, this design opens the door for tool-free, soldering-free installation. Whether you are working with low-density or high-density LED strips, our parallel circuit layout allows for easy integration with soldering-free connectors, making installation faster, safer, and more efficient. This is particularly valuable for installers, designers, and contractors who need both speed and reliability on-site.

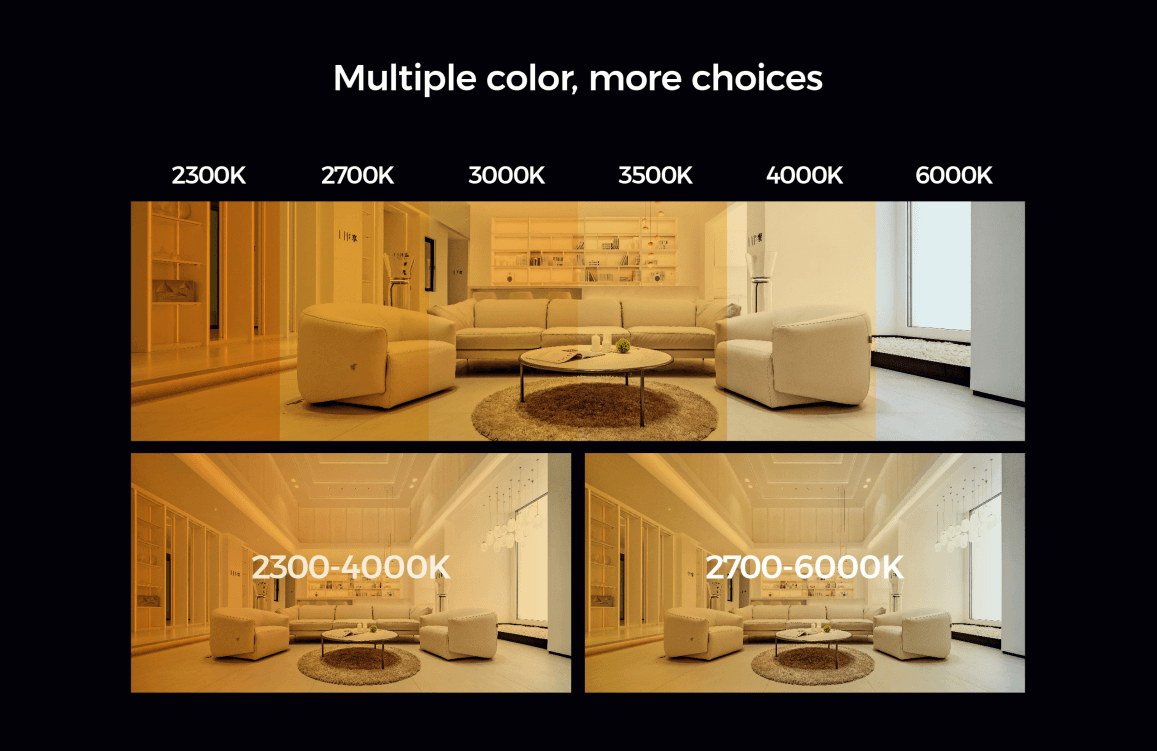

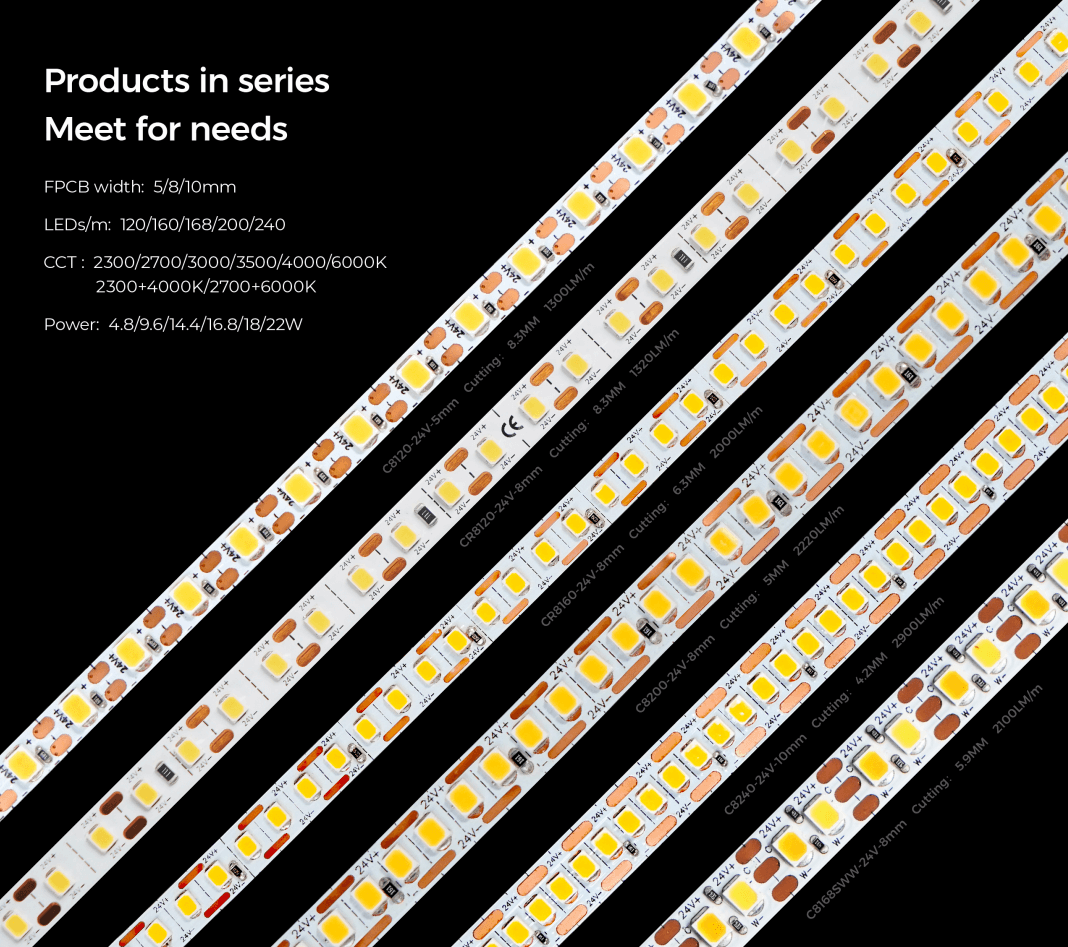

Multiple Options

Our Free Cutting Series LED strip lights are the most comprehensive strips on the market, with multiple color options, single white range from 2300 to 6000 Kelvin, tunable color range from 2300 plus 4000 Kelvin, or from 2700 plus 6000 Kelvin, or any two of the single color. It has multiple LED density options, ranging from 120 to 240 LEDs per meter. It has multiple power options, ranging from 4.8 to 22W per meter. It has multiple width options, ranging from 5 to 10 millimetres.

Benefits of the Free Cutting Series LED strips

No Soldering Requirement

The Free Cutting Series LED strip lights are solder-free connectors which match ultra-slim strips from 5mm to 10mm with 120 LEDs/meter low density to 240 LEDs/meter high density. You can cut and connect strips freely without needing any soldering equipment or trained personnel.

Traditionally, high-density LED strips are designed in series circuits. If the strip is not cut correctly or if a component or LED fails, the circuit can be interrupted, which could lead to "short-circuits, dimming problems, or complete failure". Customization is risky, and installation flexibility is limited.

Our Free Cutting Series LED strip lights, on the other hand, use "parallel circuit architecture", which allows each segment to work independently. You can now cut the strip wherever you want without having to worry about safety or electrical issues. The rest of the strip "continues to function normally" even if a section is damaged or sliced. This provides a reliable and stable lighting solution.

Reduced Stock Keeping unit (SKU)

The Free Cutting Series has a 2-in-1 integrated feature which allows both free cutting and a high efficiency of up to 140lm/W at CRI90. These strips will reduce your stock by 50%.

Environmentally-Friendly Packaging

Free Cutting Series LED strip lights are not only engineered for maximum flexibility and reliability, but also packaged with sustainability in mind. It comes in environmentally-friendly packaging that has a reel paper content above 99% and an anti-static bag paper content above 60%. This is higher than the European Commission standards of packaging paper, which requires at least 50% content.

Conclusion

The Free Cutting Series LED strips redefines what’s possible with LED strip lighting. Featuring customized 24V chips and a parallel FPCB design, these strips allow true free cutting without compromising safety or performance. Even if one segment is damaged, the rest keeps working, ensuring long-lasting reliability. With tool-free, soldering-free connectors and multiple options in color temperature, density, width, and power, installation is faster, easier, and more flexible than ever. What's more, eco-friendly packaging reflects our commitment to sustainability.

Whether you are lighting architectural facades, interiors, or commercial spaces, Free Cutting Series offers unmatched flexibility and efficiency. It is not just a product, it is part of our mission to create an ideal lighting space for the world.

COLORS Lighting, the LED linear lighting solutions provider, specialises in the research, development, and manufacturing of high-quality lighting products, which have been certified by all major national markets and are exported to more than 100 countries and regions worldwide.

Our product portfolio covers Neon Strips, LED Strips, Infinite Lights, Linear Lights, Track lights, and Downlights. COLORS Lighting provides integrated and professional lighting solutions for residential, hotel, office, commercial, and outdoor spaces.

We have a professional lighting design team, key projects to provide pre-design planning, mid-term selection simulation, post-installation and commissioning of professional support. For key projects, we can cooperate with designers and engineers to deepen the pre-sale product application program. Welcome to contact us and tell us which products you prefer, or let us know what type of lighting solution you need. Let us help your lighting project! COLORS Lighting, Colorful Life!