Blog

Common Issues, Causes, and Optimization Strategies in Architectural Façade Lighting Projects

Common Issues, Causes, and Optimization Strategies in Architectural Façade Lighting Projects

Ryan Lee.UpdatedJune 27, 2025|15 mins Read

Introduction

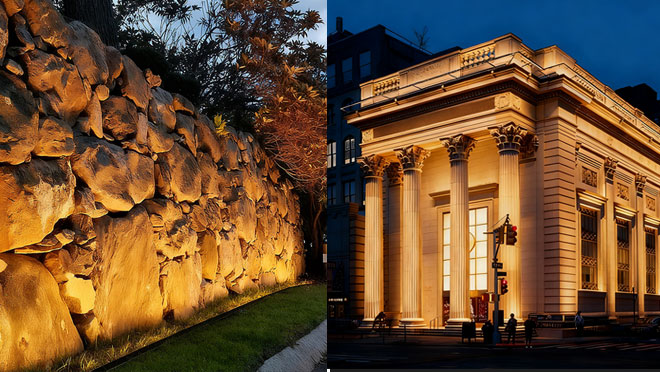

Architectural facade lighting is designed to transform a building's nighttime appearance through artistic expression. It uses artificial light sources and systematic lighting design to emphasize the building's structural features, texture, and cultural connotations, while achieving harmonious integration into the urban environment. In actual engineering projects, however, problems can arise at various stages, including lighting design, product choice, construction implementation, operational management, and so on. This prevents the best facade lighting performance as well as long-term sustainability.

I. Systematic Issues in the Design Phase

1. Light Pollution and Energy Overuse

Excessive emphasis on brightness leads to overpowered luminaires and the absence of intelligent dimming systems, causing glare and uncontrolled energy consumption.

Examples include floodlighting in residential zones, glare from reflective curtain walls in commercial areas, and exposed linear lights causing spill light.

Cause: Poor balance between aesthetics and technical constraints; neglect of luminance standards outlined in Urban Nightscape Lighting Design Codes.

2. Lack of Cultural Identity

Urban lighting has become highly homogenized. Historical buildings are often damaged by modern dynamic LEDs, and imitation classical buildings suffer from excessive color outlining, resulting in visual fatigue and a lack of uniqueness. Landmark projects may ignore regional characteristics.

Cause: Insufficient urban context research in early design phases; reliance on standardized templates.

3. Flat Lighting Layers

The excessive use of contour lighting has resulted in the loss of the building's three-dimensionality. The uniform brightness of the linear outlines has caused the building to lose its light and shadow layers, particularly for buildings with glass curtain walls or complex geometric forms, which obscures the texture of the materials and the spatial relationships between the building's elements. The imbalance between accent lighting and ambient lighting, coupled with the failure to consider the visual differences between different viewpoints (pedestrian, vehicular, and aerial), has further exacerbated these issues.

Cause: Lack of 3D modeling and dynamic simulation across multiple periods.

4. Risks of Dynamic Lighting

Dynamic lighting can enhance visual impact via color changes and brightness variations, but excessive use can lead to the following issues:

Circadian Rhythm Disruption: High-frequency flicker (>4Hz) and excessive blue light (>5000K) suppress melatonin and affect sleep.

Traffic Hazards: Media façades near intersections distract drivers; dynamic modes should be prohibited within visual triangles.

Energy and Maintenance Burden: RGB LED screens consume 300–500W/m²; dynamic control systems fail 40% more often than static systems due to protocol mismatches (e.g., DMX512 incompatibility).

Design Optimization Strategies:

1) Multi-dimensional Design Collaboration: Align architecture, façade, electrical, and landscape through BIM and dynamic lighting simulation for daytime and nighttime previews.

2) Hybrid Lighting Schemes: Combine techniques by zone—for example, top floors with backlighting, mid-sections with wall washing, and lower façades with floodlights to highlight the texture.

3) Dynamic Control Algorithm Optimization: Use time and zone-based control algorithms. Limit lighting to outlines on weekdays, and activate dynamic modes during festivals to reduce energy.

4) Light Pollution Mitigation: Use asymmetric beam optics to limit upward light.

5) Apply internal lighting for glass façades instead of exterior projection.

II. Quality Issues in Product Selection

1. Uncontrolled LED Lumen Depreciation

Low-quality chips degrade by over 50% within 3 years. Poor thermal design raises junction temperatures above 85°C. This is mainly due to cost-oriented procurement decisions, as the product does not require an LM-80 test report.

2. Fixture Reliability Issues

IP65-rated fixtures fail during typhoons due to water ingress. Coastal corrosion leads to junction box rusting. Power supplies fail within 3 years due to capacitor-based design. Failure to meet GB7000.1-2015 environmental testing, no reliability certification for drivers.

3. Poor Optical Precision

Asymmetric lenses deviate beyond ±15% from intended beam angles, causing overexposure of adjacent façades. Optical molds fail to meet IES classification standards.

4. Poor system compatibility

Control protocols are often incompatible (e.g., DALI vs. KNX), and confusing extension cable specifications lead to excessive voltage drops.

5. Delayed Customization

Custom fixtures for irregular geometries take 3–6 months to develop, delaying project schedules.

Product Optimization Strategies:

1) Lifecycle Product Standards: Develop an enterprise-level Façade Lighting Technical White Paper, specifying IP68, -40°C to +85°C temperature range, L80B10 lifespan ≥ 50,000 hours. Promote capacitor-free drivers and potting-based heat dissipation.

2) Modular Product Systems: Develop modular linear systems (1m/2m/3m with curved connectors) for complex surfaces. Use a "base luminaire + smart module" architecture for future functional upgrades.

3) Ecosystem Collaboration: Establish joint labs among lighting manufacturers, controller vendors, and design institutes to pre-verify system compatibility.

III. Technical Faults During Construction

1. Fixture Installation Defects

Projection angle deviations of more than 5° create uneven brightness. Misaligned embedded anchors (more than 5cm) cause fixture misplacement. Inadequate cable waterproofing leads to short circuits. High-rise projects lack maintenance access, window-cleaning track absence increases installation risk. Late-stage rework occurs when façades are sealed before fixture installation.

Cause: Inaccurate 3D coordinates; BIM coordination not enforced.

2. Control System Failures

A mismatch between dimming modules and fixture protocols (e.g., DALI vs. DMX). Light sensors are installed in the wrong position (e.g., the sensor in a shaded area misjudges the ambient brightness).

Cause: Poor technical handover between system integrators and fixture manufacturers.

3. Special Material Compatibility Issues

Color temperature deviation in stone façades causes a blueish tint. Backlit glass creates a "black hole" effect. Oxidized copper reduces reflectivity by 30%.

Cause: Lack of material spectral reflectance testing.

Implementation Optimization Strategies:

1) Digital Construction Simulation: Combine laser scanning and AR technology during façade panel fabrication to mark exact luminaire points; use BIM conflict detection to avoid spatial collisions with steel structures and piping systems.

2) Modular Construction Innovation: Promote "façade and lighting integration" panels with 90% wiring pre-done in the factory. Use magnetic quick-mount light strips to reduce high-altitude welding.

3) Full Schedule Coordination: Create a workflow coupling matrix between lighting, façade, and MEP—for example, embed lighting conduits within 7 days of façade framework completion.

IV. Long-Term Operations & Maintenance Challenges

1. Inefficient Fault Detection and Lack of Repair Channels

Manual inspection of single-point failures is slow. Areas above 30m often lack catwalks. Rope access operations are 8 times costlier than ground maintenance.

Cause: Poor collaboration between architects and lighting designers.

2. No Energy Monitoring

90% of projects lack circuit-level metering, preventing the identification of abnormal energy use (e.g., leakage causing 300% overconsumption).

Cause: Incomplete smart lighting system infrastructure.

3. Difficult Retrofit and Upgrades

DMX512 systems from a decade ago are incompatible with new control consoles. Blocked conduits make rewiring 3 times more expensive.

Cause: Lack of 20% design margin for future upgrades.

Operations & Maintenance Optimization Strategies:

Integrate LCC (Life Cycle Cost) analysis and virtual reality tools during design to enable full digital management across design, construction, and O&M. Learn from major projects like the Palace Museum retrofit: establish a database of spectral properties, failure cases, and energy benchmarks.

1) Smart O&M System: Deploy IoT sensors every 50m of light strip to monitor voltage, temperature, and humidity. Use AI fault diagnostics to analyze current waveforms and locate faults.

2) Preventive Maintenance System: Develop a Lighting System Health Index - trigger alerts when 80% of product lifetime is reached. Build regional repair hubs equipped with drones for lamp replacement.

3) Energy Optimization: Monitor lighting carbon emissions, and adjust lighting schedules seasonally (e.g., later turn-on in summer). Promote ESCO (Energy Service Company) and lighting insurance models to reinvest savings into maintenance.

Conclusion

To ensure both optimal performance and long-term reliability of architectural façade lighting, a holistic approach across all project stages is essential:

Design: Avoid one-size-fits-all techniques, enhance spatial depth, and preserve local cultural character.

Product: Rigorously control power supply and thermal quality, boost environmental resilience.

Construction: Strengthen multidisciplinary collaboration, and adopt modular and prefabricated solutions.

Operation & Maintenance: Employ smart monitoring and preventive maintenance protocols.

Systematic improvements across the entire lifecycle can achieve a balance between aesthetic excellence, functional reliability, and sustainable urban development.

COLORS Lighting, the LED linear lighting solutions provider, specialises in the research, development, and manufacturing of high-quality lighting products, which have been certified by all major national markets and are exported to more than 100 countries and regions worldwide.

Our product portfolio covers Neon Strips, LED Strips, Infinite Lights, Linear Lights, Track lights, and Downlights. COLORS Lighting provides integrated and professional lighting solutions for residential, hotel, office, commercial, and outdoor spaces.

We have a professional lighting design team, key projects to provide pre-design planning, mid-term selection simulation, post-installation and commissioning of professional support. For key projects, we can cooperate with designers and engineers to deepen the pre-sale product application program. Welcome to contact us and tell us which products you prefer, or let us know what type of lighting solution you need. Let us help your lighting project! COLORS Lighting, Colorful Life!